Efficient Storage Solutions with Warehouse Roller Racking Systems for Optimal Space Utilization

Ліст . 27, 2024 01:49

Understanding Warehouse Roller Racking Systems

In the evolving landscape of logistics and warehousing, efficiency and space optimization are essential for maintaining a competitive edge. One of the innovative solutions that have gained popularity in recent years is the warehouse roller racking system. This article delves into what these systems are, their advantages, types, applications, and considerations for implementation.

What are Warehouse Roller Racking Systems?

Warehouse roller racking systems are storage solutions designed to facilitate the easy movement and retrieval of goods within a warehouse. They comprise a series of horizontal rails or tracks equipped with rollers that allow items, typically stored on pallets, to glide smoothly from one end of the racking to another. This mechanism promotes a first-in, first-out (FIFO) inventory system, ensuring that older stock is used before newer stock, which is vital for businesses handling perishable or time-sensitive products.

Advantages of Roller Racking Systems

1. Space Efficiency One of the most significant advantages of warehouse roller racking systems is their ability to maximize vertical space. Businesses can stack goods higher than traditional racking systems while still allowing easy access to each level.

2. Improved Accessibility The rollers enable quick access to goods, reducing the time employees spend retrieving items. This is particularly beneficial in environments where speed is crucial, such as in distribution centers or e-commerce fulfillment centers.

3. Increased Operational Efficiency With improved access and reduced retrieval times, warehouses can increase their throughput, meaning they can handle a larger volume of goods in shorter periods, enhancing overall productivity.

4. Enhanced Safety Roller racking systems minimize the need for forklifts to maneuver in tight spaces, reducing the risk of accidents. Additionally, the design allows for more organized and orderly storage, which helps prevent workplace injuries.

5. Versatility These systems can be customized to fit various product types, sizes, and weight, providing a flexible solution for warehouses of all kinds.

Types of Roller Racking Systems

There are generally two types of roller racking systems in warehouse applications

1. Gravity Roller Racking This system uses gravity to move goods along the racking. The incline allows products to roll down to the picking area, facilitating quick access. Gravity systems are particularly efficient for FIFO stock management.

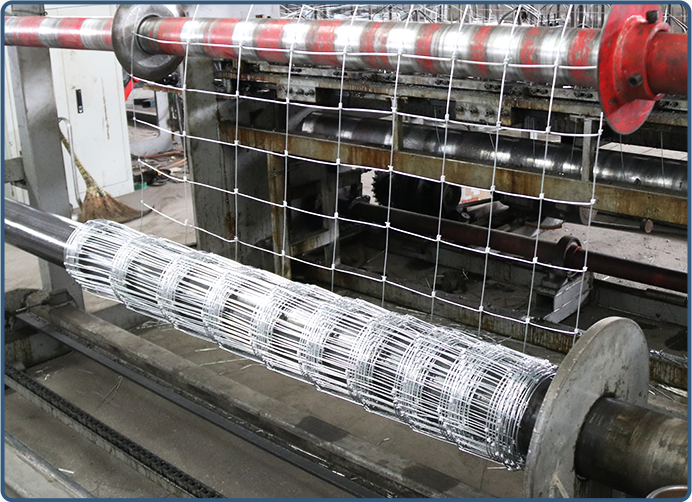

warehouse roller racking systems

2. Powered Roller Racking Unlike gravity systems, powered roller racking uses electric motors to move goods along the racking. These systems can be integrated into automated warehousing solutions, allowing for even greater efficiency and streamlined operations.

Applications of Roller Racking Systems

Warehouse roller racking systems are versatile and can be utilized in various industries, including

- Food and Beverage Due to their FIFO capabilities, roller racking systems are ideal for perishable goods. - Retail E-commerce and retail operations benefit from the quick access and organization these systems offer. - Pharmaceuticals The need for organized and efficient stock management makes roller racking an excellent choice. - Manufacturing These systems can streamline the supply chain, reducing lead times and improving stock accuracy.

Considerations for Implementation

While warehouse roller racking systems offer numerous benefits, businesses should consider several factors before implementation

1. Space Assessment Analyzing the warehouse space is crucial. Roller racking systems require sufficient ceiling height and floor space to operate efficiently.

2. Type of Goods Understanding the types and sizes of goods to be stored will help determine the appropriate racking system to implement.

3. Cost While roller racking systems can reduce operational costs in the long run, upfront investments can be significant. Businesses must evaluate their budget accordingly.

4. Safety Regulations Compliance with local safety regulations is vital in the design and implementation of any warehousing solution.

5. Maintenance Needs Regular maintenance checks are essential to ensure the rollers and mechanisms function correctly and safely.

Conclusion

In conclusion, warehouse roller racking systems represent a practical and innovative solution for modern warehouses aiming to enhance efficiency and improve inventory management. With their ability to maximize space, streamline operations, and increase safety, they are becoming an integral component of effective warehouse logistics. By carefully assessing their specific needs and considering the various options available, businesses can leverage roller racking systems to maintain competitiveness in a fast-paced market.