Bending Techniques for Steel Edging A Comprehensive Guide for Beginners

Nov . 01, 2024 12:29

The Art of Bending Steel Edging A Guide to Precision and Durability

Steel edging has become a staple in modern landscaping, providing both aesthetic appeal and functional boundaries for garden beds, walkways, and driveways. One of the most crucial aspects of working with steel edging is the technique of bending it to create smooth curves and seamless transitions. This article will delve into the process of bending steel edging, exploring both the tools required and the benefits it offers to any landscaping project.

Understanding Steel Edging

Steel edging is typically made from high-quality steel that is resistant to rust and weather damage, ensuring durability and longevity. Available in various thicknesses and finishes, it can enhance the visual appeal of gardens and create organized, defined spaces. The flexibility of steel edging allows homeowners and landscapers to create unique designs that complement the existing landscape.

Tools and Materials Needed

To effectively bend steel edging, it is essential to have a few key tools on hand

1. Steel Edging Select the right thickness depending on your project needs. Thicker edging is more robust but may be more challenging to bend. 2. Bending Tool A manual or hydraulic bender specifically designed for steel edging will make the process much easier and more precise.

3. Hammer and Anvil For minor adjustments, a hammer and anvil can help you shape the steel edging by hand if you don’t require large curves.

4. Safety Gear Always wear gloves and eye protection when working with metal to ensure safety.

Bending Process

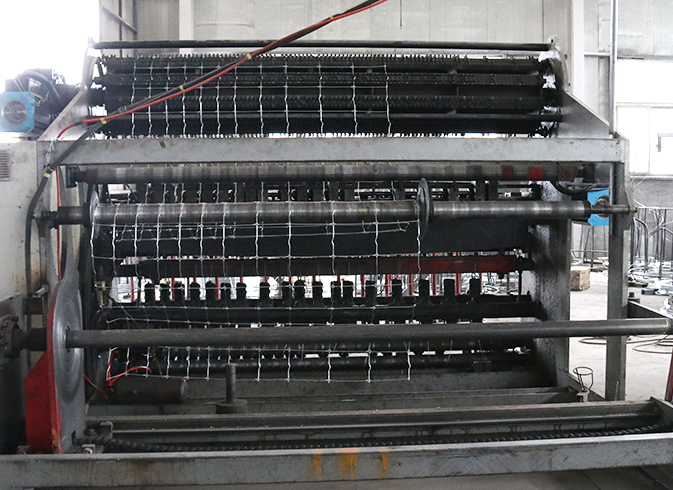

bending steel edging

1. Measure and Mark Before bending, measure the area where the edging will be installed. Mark the desired curve lengths on the steel edging to guide your bending process.

2. Secure the Edging Clamp the steel edging into your bending tool and ensure it is secure to prevent movement during the bending process.

3. Adjust for Curvature Depending on the tightness of the desired curve, gradually apply pressure to the bending tool. Take your time to achieve an even curve without kinks or sharp angles.

4. Finishing Touches After bending, inspect the steel edging for any rough edges. Use a file to smooth out these areas, preventing potential injury during installation.

Advantages of Bending Steel Edging

Bending steel edging not only adds visual interest to landscape design but also offers practical benefits. Curved edges can guide water runoff efficiently, preventing erosion and maintaining the integrity of flower beds and lawns. Moreover, customizable designs allow for creativity in landscaping, enabling homeowners to showcase their style.

Additionally, steel edging is low-maintenance compared to other materials such as wood or plastic, which may warp or rot over time. With proper installation and care, steel edging can last many years, providing a sturdy border without the need for frequent replacement.

Conclusion

The ability to bend steel edging opens up a world of creative possibilities for landscape design. By understanding the process and preparing the necessary tools, homeowners can efficiently create beautiful, functional outdoor spaces. Whether you're a professional landscaper or a DIY enthusiast, mastering the art of bending steel edging will undoubtedly enhance your projects, blending functionality with artistic expression.