Exploring the Benefits of Mobile Warehouse Racking Systems for Efficient Storage Solutions

Ago . 15, 2024 16:15

The Benefits and Applications of Movable Warehouse Racking

In the ever-evolving world of logistics and warehousing, efficiency is key to maintaining productivity and minimizing costs. One innovative solution that has gained popularity in recent years is movable warehouse racking. This system offers a dynamic and adaptable approach to storage, catering to the diverse needs of modern warehouses.

Movable warehouse racking, also known as mobile shelving or mobile storage systems, is designed to maximize storage capacity within a limited space. Unlike traditional static shelving, movable racking consists of shelves mounted on wheeled bases that can be moved side to side. This mobility allows warehouse operators to eliminate the need for multiple access aisles usually required in conventional racking systems. As a result, the available storage area is utilized more efficiently, leading to a significant increase in capacity.

One of the primary benefits of movable warehouse racking is its ability to streamline operations. With conventional racking systems, employees often spend considerable time navigating through aisles to locate and retrieve items. In contrast, movable racking allows for a more organized layout where shelves can be easily repositioned to create wider aisles as needed. This not only speeds up the picking process but also enhances overall workflow, allowing staff to focus on their core responsibilities without unnecessary delays.

Furthermore, movable warehouse racking systems are highly versatile. They can be configured to store a wide variety of items, from small parts and tools to larger products. This adaptability makes them particularly beneficial in industries where inventory types and sizes frequently change. For instance, in a distribution center handling seasonal products, movable racking can be adjusted to accommodate fluctuating inventory levels. This flexibility helps businesses respond quickly to changing demands, ultimately improving customer satisfaction.

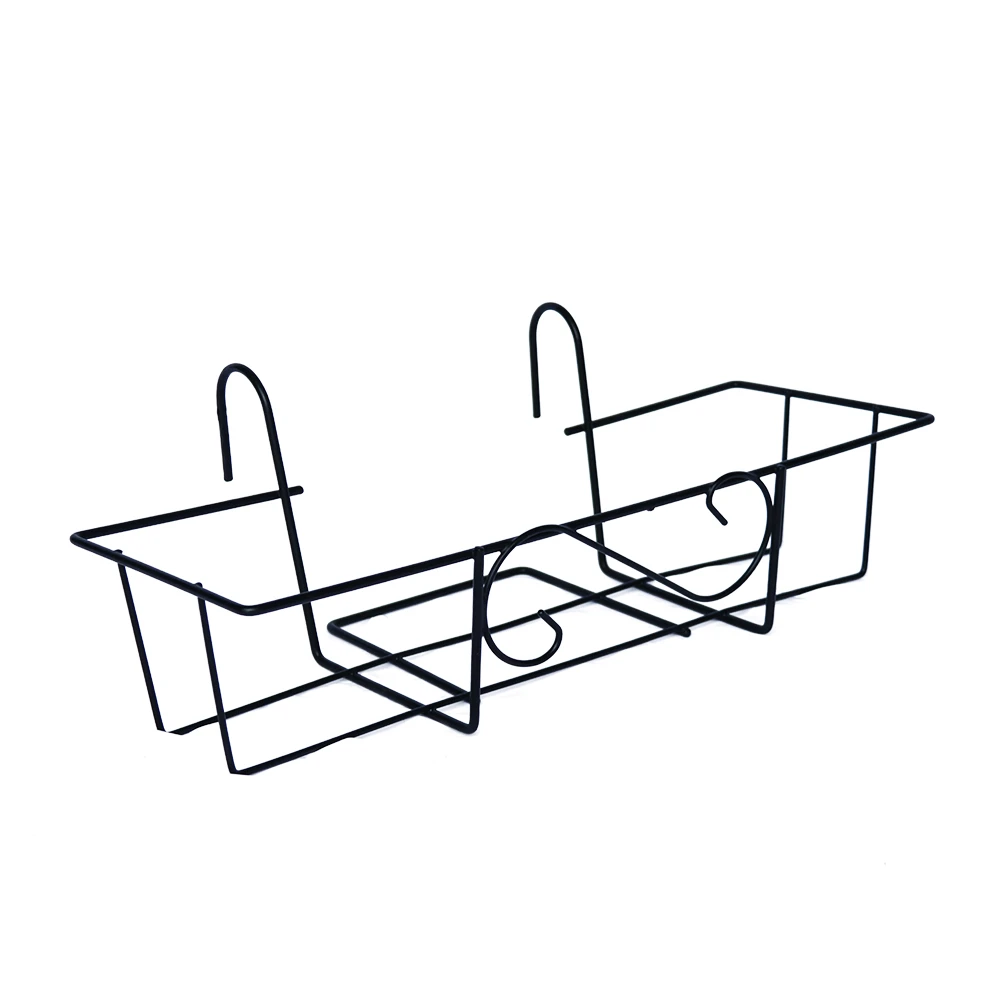

movable warehouse racking

Safety is another paramount concern in warehouse operations. Movable racking systems can be designed with safety features that protect employees and goods. For example, many systems come equipped with locking mechanisms that prevent accidental movement of racks during operation. Additionally, they can be tailored to comply with safety regulations, ensuring that warehouses protect both their workers and their inventory.

Moreover, the adoption of movable warehouse racking is not solely about efficiency and adaptability; it also has significant economic implications. By optimizing the use of vertical and horizontal space, businesses can postpone or entirely avoid costly expansions or relocations. This cost-effectiveness is particularly attractive for small to medium-sized enterprises looking to grow without the burden of excessive investment in real estate.

As technology continues to advance, the integration of movable warehouse racking with automated systems is becoming more common. Innovative solutions, such as robotic picking systems or automated guided vehicles (AGVs), can work in conjunction with movable racking to further enhance efficiency. This marriage of technology and storage solutions is paving the way for the smart warehouses of the future, where every square foot is utilized to its fullest potential.

In conclusion, movable warehouse racking presents an array of advantages for businesses looking to optimize their storage solutions. From increased capacity and improved workflow to enhanced safety and cost-effectiveness, the benefits are clear. As industries continue to adapt to changing market demands, implementing movable racking systems may very well be a key strategy for achieving operational excellence in warehousing and logistics.

Unity

Unity Creation

Creation Challenge

Challenge Contribution

Contribution