gi iron wire

Nov . 11, 2024 07:53

Exploring the Versatility of GI Iron Wire

Galvanized iron (GI) wire is a commonly used material in various sectors due to its durability, resistance to rust, and versatility. The process of galvanization involves coating iron or steel with a layer of zinc to prevent corrosion, thereby extending the life of the wire and enhancing its usability.

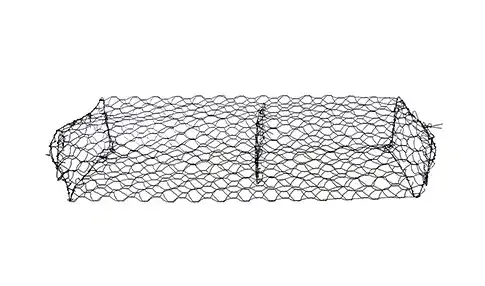

One of the primary uses of GI iron wire is in construction. It serves as a robust and reliable material for reinforcing concrete structures, such as beams and columns. The corrosion-resistant properties of galvanized wire make it an ideal choice for construction in regions with high humidity or exposure to the elements, where traditional iron would quickly deteriorate. Furthermore, GI wire is often utilized in the manufacturing of barbed wire and chain link fencing, providing security and boundaries for properties, agricultural land, and commercial areas.

Exploring the Versatility of GI Iron Wire

The versatility of GI iron wire extends to the crafting of various products. Its malleability allows it to be easily shaped into different forms, making it a favorite among artisans and metalworkers. From decorative items to functional tools, the applications are virtually limitless. In many households, GI wire is found in DIY projects, showcasing its flexibility and the ease with which it can be manipulated.

gi iron wire

Another significant impact of GI iron wire is observed in the manufacturing industries. It is used in producing various mechanical components, including springs and wire frames. The strength and durability of galvanized wire ensure that these components can withstand high tension and stress, making them essential in manufacturing durable goods. Moreover, the automotive industry also benefits from GI wire, using it in various applications, such as in the construction of vehicle frames and components.

Additionally, GI wire has a crucial role in the telecommunications sector. It is used for making telephone and internet transmission lines. The durability and rust resistance of galvanized wire ensure that communication systems remain operational over time, even under harsh weather conditions. Thus, the reliability of GI iron wire contributes significantly to the maintenance of modern connectivity.

In the realm of arts and crafts, DIY enthusiasts and professionals alike utilize GI wire for creating functional art pieces, sculptures, and home décor. Its workability allows for intricate designs, providing an avenue for creative expression. The aesthetic appeal of galvanized iron lends a rustic charm that has become increasingly popular in interior design.

In conclusion, GI iron wire is a multi-faceted material that is integral to numerous industries and applications. Its strength, durability, and resistance to rust enhance its appeal, making it a favored choice for professionals and DIY enthusiasts alike. From construction to agriculture, telecommunications, and artistic endeavors, GI iron wire has proven to be an essential component in various aspects of modern life, showcasing its versatility and indispensable nature. As we continue to innovate and explore new applications, the future of GI iron wire looks promising, paving the way for even more uses in the years to come.

Unity

Unity Creation

Creation Challenge

Challenge Contribution

Contribution