Precision Straight Cut Wire - Pre-Straightened & Ready-to-Use

Ago . 08, 2025 02:00

In the vast landscape of industrial materials, few components are as foundational and versatile as wire. Among its many forms, straight cut wire stands out as a critical element, serving countless applications from construction and agriculture to manufacturing and packaging. Also known by terms like straight and cut wire or straightened wire, this product is precisely engineered to deliver consistency, reliability, and ease of use in diverse operational environments. This comprehensive guide delves into the world of this essential material, exploring its market dynamics, technical specifications, manufacturing intricacies, and the compelling advantages it offers. We will also examine its real-world applications, highlight why Hebei Metals' Straight Binding Wire is a preferred choice, and provide insights into custom solutions, ensuring you gain a holistic understanding of this indispensable industrial product.

Understanding the Market: Industry Trends for Straight Cut Wire

The global demand for straight cut wire is robust and continues to grow, driven by burgeoning infrastructure development, expanding manufacturing sectors, and innovations in packaging and agricultural practices. According to recent market analysis, the global steel wire market, of which straight cut wire is a significant component, is projected to reach approximately USD 120 billion by 2027, growing at a CAGR of around 4-5% from 2021. Key growth drivers include:

- Urbanization and Infrastructure Development: Rapid urbanization, especially in emerging economies, necessitates extensive construction activities, from residential and commercial buildings to roads, bridges, and public utilities. Straight cut wire is indispensable in rebar tying, fencing, and general construction applications.

- Agricultural Advancements: Modern agriculture relies heavily on wire products for trellising, fencing, and baling. The demand for straightened wire for vineyard support, crop protection, and hay baling is steadily increasing.

- Packaging Industry Innovation: The packaging sector utilizes cut straight wire for securing bundles, creating robust closures, and automating packaging lines, benefiting from the wire's consistent length and strength.

- Manufacturing and Fabrication: From crafting intricate components to basic assembly, manufacturers rely on the precise dimensions and material properties of straight cut wire for efficient production.

- Sustainability Initiatives: As industries shift towards more sustainable practices, the recyclability and long lifespan of steel wire products, including straight cut wire, make them an attractive option, contributing to a circular economy.

The trend towards automation and precision manufacturing further amplifies the need for high-quality, uniformly cut wire, making the reliability of suppliers like Hebei Metals paramount.

Technical Parameters and Specifications of Straight Cut Wire

The performance and suitability of straight cut wire for specific applications hinge on its precise technical parameters. These specifications dictate the wire's strength, flexibility, corrosion resistance, and overall usability. Key parameters typically include:

- Material Grade: Most commonly, straight cut wire is made from low carbon steel (e.g., Q195, SAE 1006/1008), which offers excellent ductility and formability, making it ideal for bending and tying. For applications requiring higher strength or corrosion resistance, galvanized steel wire (zinc-coated) or stainless steel wire (e.g., SS304, SS316) may be used.

- Wire Diameter (Gauge): This is a critical dimension, affecting tensile strength and flexibility. Diameters typically range from 0.8 mm (approx. 20 Gauge) to 5.0 mm (approx. 6 Gauge), though custom sizes are available. Common gauges include 16 GA (1.6mm), 18 GA (1.2mm), and 20 GA (0.9mm).

- Tensile Strength: Measures the maximum stress the wire can withstand before breaking. For low carbon steel, this usually falls between 350-550 N/mm² (50,000-80,000 PSI), depending on the drawing process and heat treatment.

- Elongation: Indicates the wire's ductility – its ability to stretch before breaking. A higher elongation percentage (typically 10-25%) signifies better flexibility, crucial for bending and tying applications.

- Length Tolerance: Given that the wire is "cut straight," precision in length is vital. Standard tolerances are usually ±1 mm to ±5 mm, depending on the wire length and application.

- Surface Treatment: Bare (black annealed) wire offers good malleability but is susceptible to rust. Galvanized wire provides superior corrosion resistance due to its zinc coating (available in electro-galvanized or hot-dip galvanized), while PVC-coated wire offers aesthetic appeal and enhanced protection.

Typical Specifications for Straight Cut Wire

Image 1: Illustrating the versatility of straight cut wire in various construction applications.

| Parameter | Common Range (Low Carbon Steel) | Hebei Metals' Straight Binding Wire |

|---|---|---|

| Material Grade | Q195, SAE 1006/1008 | High-quality Q195/SAE 1008 Low Carbon Steel |

| Wire Diameter | 0.8 mm - 5.0 mm (20 - 6 Gauge) | 0.8 mm - 4.0 mm (12 - 20 Gauge) |

| Tensile Strength | 350 - 550 N/mm² | 380 - 480 N/mm² (Optimized for binding) |

| Elongation | 10% - 25% | ≥ 15% (Ensures excellent ductility) |

| Length Range | 200 mm - 6000 mm | 250 mm - 5000 mm (Customizable) |

| Length Tolerance | ±1 mm to ±5 mm | ±2 mm (Industry-leading precision) |

| Surface Treatment | Black Annealed, Electro-Galvanized, Hot-Dip Galvanized, PVC Coated | Black Annealed, Electro-Galvanized, Hot-Dip Galvanized |

| Zinc Coating (Galvanized) | 10-80 g/m² | 15-60 g/m² (ASTM A641 compliant options) |

This table highlights Hebei Metals' commitment to exceeding standard industry expectations, particularly with the optimized tensile strength and superior length tolerance for our flagship product, the Straight Binding Wire, available at https://www.hebeimetals.com/straight-bindng-wire.html.

Manufacturing Excellence: The Process of Creating Straight Cut Wire

The production of high-quality straight cut wire is a sophisticated process that demands precision, advanced machinery, and rigorous quality control. It typically involves several key stages, starting from raw material preparation to the final cutting and packaging.

Detailed Manufacturing Process for Straight Cut Wire

At Hebei Metals, our manufacturing process for Straight Binding Wire adheres to international standards like ISO 9001:2015, ensuring consistent quality and performance. While traditional wire manufacturing involves drawing, annealing is a critical step for black annealed wire to achieve desired ductility.

Step-by-Step Elaboration:

Raw Material Acquisition (Wire Rod Coil)

The process begins with high-quality wire rod coils, typically made from low carbon steel (e.g., Q195, SAE 1006, SAE 1008). These coils are sourced from reputable steel mills that comply with international material standards like ASTM A510 or equivalent.

Pickling and Rinsing

Before drawing, the wire rod undergoes a pickling process. This involves immersing the coil in an acid solution (e.g., hydrochloric acid) to remove rust, scale, and other impurities from the surface. This step is crucial for preventing die wear during drawing and ensuring a clean surface for subsequent treatments. After pickling, the wire is thoroughly rinsed to remove any acid residue.

Wire Drawing

The pickled wire rod is then fed into a series of drawing dies. Wire drawing is a cold working process where the wire is pulled through progressively smaller dies, reducing its diameter and increasing its tensile strength. This process elongates the wire and refines its grain structure, enhancing its mechanical properties. Multiple drawing passes might be required to achieve the desired final diameter.

Heat Treatment (Annealing) or Surface Treatment (Galvanizing)

This is a critical divergence point depending on the desired end product:

- Black Annealed Wire: For black annealed straight cut wire, the drawn wire undergoes an annealing process. This involves heating the wire to a specific temperature (e.g., 700-900°C) and then slowly cooling it. Annealing softens the wire, increases its ductility, and removes internal stresses introduced during drawing, making it highly pliable and easy to tie. This is crucial for products like Straight Binding Wire.

- Galvanized Wire: For galvanized straight cut wire, the drawn wire (sometimes after an initial annealing if higher ductility is required) is coated with a layer of zinc. This can be done via electro-galvanizing (electrolytic deposition, thinner coating) or hot-dip galvanizing (immersion in molten zinc, thicker and more durable coating). The zinc coating provides excellent corrosion resistance, extending the wire's lifespan, especially in outdoor or humid environments.

Image 2: Modern machinery used for straightening and cutting wire with high precision.

Straightening and Cutting

The treated wire (annealed or galvanized) is then fed into an advanced straightening and cutting machine. This machine pulls the wire through a series of rollers and guides that remove any curvature or kinks, ensuring it is perfectly straight. Once straightened, the wire is cut to precise, pre-set lengths using a high-speed cutting mechanism. Modern machines utilize CNC technology to achieve exceptional length accuracy and minimize waste, a key feature in producing reliable cut straight wire.

Quality Inspection and Packaging

The final stage involves rigorous quality control. Each batch of straight cut wire undergoes comprehensive inspection for diameter, length accuracy, tensile strength, elongation, and surface finish (e.g., zinc coating thickness for galvanized wire). Adherence to standards like ASTM A853 (for general-purpose wire) and ISO 9001:2015 (quality management) is paramount. Once approved, the wire bundles are typically tied with binding wire, wrapped in plastic film, and then packed in woven bags or on wooden pallets for shipping, ensuring protection during transit.

This meticulous process ensures that every piece of straight cut wire from Hebei Metals meets the highest standards of quality and performance, delivering superior value to our customers.

Application Scenarios of Straight Cut Wire

The inherent versatility and robust properties of straight cut wire make it indispensable across a multitude of industries. Its precise length and consistent quality are critical for efficient and reliable operations. Here are some primary application scenarios:

- Construction Industry:

- Rebar Tying: Perhaps the most common use, straight binding wire (a form of straight cut wire) is used extensively to tie reinforcing steel bars (rebar) together in concrete structures. Its malleability and strength ensure a secure, stable framework before concrete pouring.

- Fencing: For creating perimeter fences, agricultural fences, or security barriers, straight and cut wire is used for tensioning lines, securing mesh, or forming components of wire fences.

- Mesh Production: Used as raw material for welded wire mesh, a common building material for walls, floors, and general reinforcement.

- Agriculture:

- Baling Wire: Essential for baling hay, straw, cotton, and other agricultural products. The uniform length and strength of straight cut wire allow for efficient and secure baling operations.

- Trellis and Support Systems: For vineyards, orchards, and certain vegetable crops, straightened wire provides crucial support, guiding plant growth and maximizing yield.

- Animal Husbandry: Used in cages, pens, and other enclosures for livestock.

- Packaging Industry:

- Bundling and Strapping: Ideal for securing bundles of timber, paper, pipes, or other industrial products for transport and storage. The consistent lengths are perfect for automated packaging lines.

- Bag Closures: Used for tying off sacks of grain, chemicals, or other bulk materials.

- Manufacturing and Fabrication:

- Hanger Production: A primary material for manufacturing clothes hangers.

- Crafts and DIY: Due to its ease of handling and precise dimensions, it's often found in various craft projects, model making, and general DIY repairs.

- Component Manufacturing: Used to create specific components for appliances, furniture, and various assemblies that require precise wire forms.

- Mining and Quarrying: Employed in various tying and securing operations, especially in shoring or reinforcing structures.

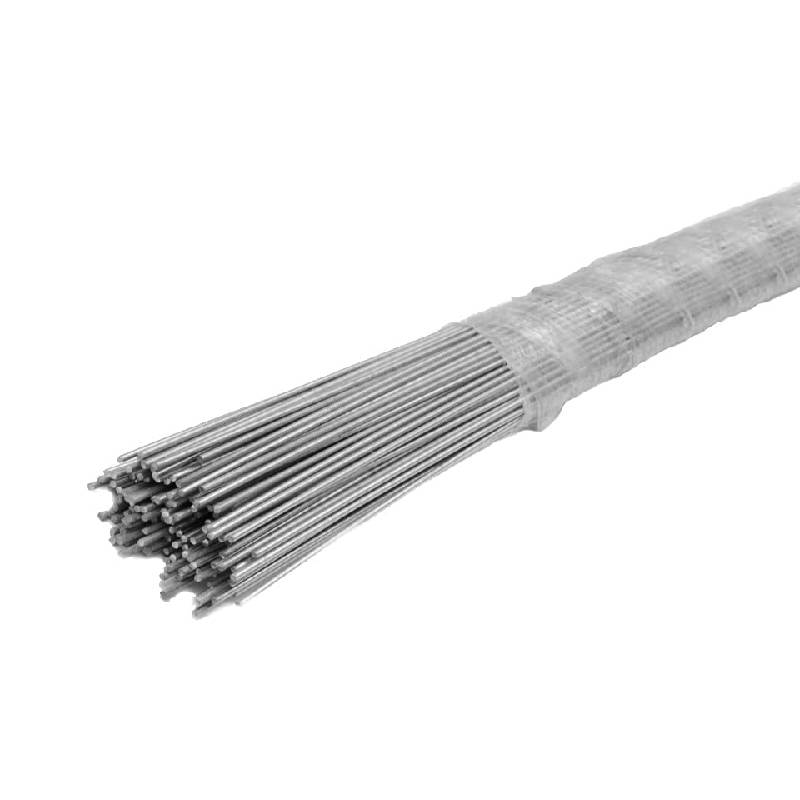

Image 3: Bundles of Straight Binding Wire, ready for distribution to various industries.

In each of these scenarios, the precision and quality of the straightened wire directly impact operational efficiency, safety, and the integrity of the end product or structure. Hebei Metals' Straight Binding Wire is specifically designed to excel in these demanding applications.

Technical Advantages of Hebei Metals' Straight Binding Wire

Choosing the right supplier for straight cut wire is paramount. Hebei Metals, with decades of experience in wire manufacturing, offers Straight Binding Wire that stands out due to its superior technical advantages, ensuring optimal performance and value for our clients. Our product, available at https://www.hebeimetals.com/straight-bindng-wire.html, embodies these benefits:

- Exceptional Straightness and Length Accuracy: Our advanced straightening and cutting machinery, often CNC-controlled, ensures minimal deviation from the specified length (typically ±2mm tolerance). This precision is crucial for automated processes, reducing waste and increasing operational efficiency in applications like rebar tying or baling.

- Optimal Ductility and Malleability: Specifically for our black annealed Straight Binding Wire, the controlled annealing process yields a product with superior pliability. This makes it incredibly easy to bend, twist, and tie, significantly reducing operator fatigue and increasing productivity on construction sites or in packaging facilities. This characteristic is often measured by elongation percentage, where our wire consistently exceeds 15%.

- High Tensile Strength for Reliable Securing: While being highly ductile, our wire retains excellent tensile strength (380-480 N/mm²). This dual characteristic ensures that once tied, the wire provides robust and secure fastening, resisting breakage under stress and maintaining the integrity of the bundle or structure.

- Superior Corrosion Resistance (for Galvanized Variants): Our hot-dip galvanized and electro-galvanized straight cut wire options feature uniform and robust zinc coatings. This protection significantly extends the wire's lifespan in harsh or outdoor environments, preventing rust and degradation and reducing the need for frequent replacement. This contributes to long-term cost savings and enhanced structural durability.

- Consistent Quality and Uniformity: Through rigorous quality control at every stage—from raw material inspection to final product testing—we ensure that every bundle of straightened wire maintains uniform diameter, consistent strength, and predictable performance. This consistency is vital for large-scale projects and automated systems, minimizing interruptions and ensuring reliable outcomes.

- Reduced Material Waste: The precise cutting and consistent quality of our cut straight wire minimize defects and off-cuts, leading to less material waste during your operations. This translates directly into cost efficiencies and supports more sustainable practices.

- Extended Service Life: Designed and manufactured to stringent standards, our wire products offer an extended service life, even under demanding conditions. This longevity reduces maintenance costs and ensures long-term reliability for critical applications in petrochemical, metallurgy, and water supply/drainage industries where our galvanized wires find particular use for support and non-structural applications.

By leveraging these technical advantages, Hebei Metals empowers businesses to achieve higher productivity, lower operational costs, and superior end-product quality.

Manufacturer Comparison: Why Choose Hebei Metals

In a competitive market, selecting the right manufacturer for straight cut wire is a critical decision that impacts project timelines, budget, and overall quality. Hebei Metals distinguishes itself through a blend of expertise, experience, and commitment to trustworthiness and authority. Here’s a comparison highlighting our unique advantages:

Manufacturer Comparison Table

| Feature | Hebei Metals | Typical Competitor A (Mass Market) | Typical Competitor B (Niche/Premium) |

|---|---|---|---|

| Product Range | Extensive, focus on high-quality wire products including Straight Binding Wire, galvanized, annealed, etc. | Limited, often basic black annealed wire only. | Specializes in specific high-end alloys or coatings. |

| Quality Standards & Certifications | ISO 9001:2015 certified; Adherence to ASTM, ANSI, DIN; Rigorous QC processes. | Basic quality checks; sometimes no formal certifications. | May have ISO, but limited to fewer product lines. |

| Precision & Tolerance | Industry-leading length tolerance (±2mm); uniform diameter. | Standard market tolerance (±5mm or more); variable diameter. | Good precision, but often at a higher price point. |

| Material Sourcing | Verifiable, premium raw materials (Q195, SAE 1008) from certified mills. | Undisclosed or lower-grade materials. | Often proprietary blends, can be expensive. |

| Customization Capabilities | Highly flexible for custom lengths, diameters, and coatings. Dedicated R&D. | Limited or no customization; standard sizes only. | May offer customization but with high minimum order quantities. |

| Service Life & Durability | Extended life due to robust manufacturing and superior coatings. | Average life, susceptible to premature degradation. | Good durability, but cost-prohibitive for many. |

| Customer Support & After-Sales | Dedicated technical support, responsive customer service, comprehensive warranty. | Minimal support; transactional only. | Decent support, but may be slow due to niche focus. |

| Industry Experience & Reputation | Decades of industry experience, established global presence, positive client testimonials. | Newer or less established players. | Established in specific niches, less broad market recognition. |

Hebei Metals' long-standing reputation as a reliable and high-quality manufacturer is built on consistently delivering products that not only meet but often exceed industry standards. Our commitment to quality, backed by a robust supply chain and advanced manufacturing facilities, positions us as an authoritative leader in the production of straightened wire.

Image 4: Rigorous quality control checks ensuring every batch of straight cut wire meets high standards.

Custom Solutions and Tailored Straight Cut Wire

While standard sizes of straight cut wire meet many needs, specific industrial applications often require bespoke solutions. Hebei Metals excels in providing highly customizable Straight Binding Wire to perfectly match your unique project requirements. Our engineering team works closely with clients to understand their exact needs, offering tailored options in:

- Custom Diameters: Beyond standard gauges, we can produce wire in precise diameters to fit specialized machinery or specific load-bearing requirements.

- Specific Lengths: Whether you need exceptionally short pieces for automated assembly or very long lengths for large-scale construction, our cutting-edge machinery can achieve custom dimensions with unparalleled accuracy.

- Material Grades: While low carbon steel is standard, we can explore other steel grades for enhanced properties like higher tensile strength, greater ductility, or specific chemical compositions, depending on application demands (e.g., aerospace, automotive).

- Surface Finishes: In addition to black annealed and galvanized options, we can discuss specialized coatings for extreme environments, aesthetic requirements, or unique friction characteristics.

- Packaging Solutions: We offer various packaging methods, including custom bundle sizes, specific coil weights, or specialized protective wrapping, to streamline your internal logistics and reduce handling costs.

Our commitment to custom solutions is underpinned by our extensive technical expertise and flexible manufacturing capabilities, ensuring that even the most niche requirements for straight cut wire are met with precision and efficiency.

Real-World Application Cases and Customer Success

Hebei Metals takes immense pride in the successful application of our straight cut wire across diverse industries globally. Our Straight Binding Wire has been instrumental in numerous projects, demonstrating its reliability, durability, and cost-effectiveness. Here are a few illustrative examples:

- Major Infrastructure Project, Middle East: A leading construction firm undertook a massive highway bridge construction. They required thousands of tons of high-quality straight binding wire for rebar tying, demanding consistent tensile strength and precise lengths to meet stringent structural integrity standards and rapid construction schedules. Hebei Metals supplied batches of 1.6mm (16 GA) black annealed straight cut wire, delivered in meticulously bundled packages. Client Feedback: "The consistency of Hebei Metals' wire significantly sped up our rebar tying process. Less breakage, easier handling. A truly reliable partner." The project was completed ahead of schedule, with the wire performing flawlessly under demanding site conditions.

- Agricultural Co-op, North America: A large agricultural cooperative needed durable and reliable straightened wire for automated hay baling. Their existing supplier's wire was prone to breaking, causing costly downtime. Hebei Metals provided galvanized straight cut wire (2.5mm, 12 GA) with enhanced zinc coating and optimized ductility. Outcome: The cooperative reported a 20% reduction in baler downtime due to wire breakage and extended the lifespan of their bales significantly, especially in humid conditions. This led to substantial cost savings and increased productivity during harvest season.

- European Manufacturing Plant: An automotive components manufacturer required precise lengths of cut straight wire for automated robotic welding lines. Any variation in length or straightness would cause significant production errors. Hebei Metals' custom-cut 1.0mm (19 GA) electro-galvanized straight cut wire, with a length tolerance of ±1mm, was chosen. Result: The plant experienced seamless integration of the wire into their automated systems, eliminating production stoppages related to wire inconsistencies and improving overall product quality and efficiency.

These cases exemplify our commitment to providing not just a product, but a reliable solution that contributes directly to our clients' success. Our long-standing relationships with global partners, some spanning over 20 years, are a testament to our authoritative position and trustworthiness in the industry.

Enhancing Trustworthiness: FAQs, Delivery, Warranty & Support

At Hebei Metals, we understand that trust is built on transparency, reliability, and robust support. We strive to provide a seamless experience for our clients, from inquiry to after-sales service. Here's how we enhance trustworthiness:

Frequently Asked Questions (FAQs)

Black annealed straight cut wire undergoes a heat treatment process (annealing) to make it exceptionally soft and pliable, ideal for easy tying and bending. It has no rust resistance. Galvanized straight cut wire, conversely, is coated with a layer of zinc after drawing, providing superior corrosion resistance, making it suitable for outdoor or humid environments where rust is a concern. The choice depends on the application's environmental conditions and required malleability.

Our wire undergoes a sophisticated straightening process using precision rollers and guides within advanced machinery. This equipment uses a combination of tension and mechanical alignment to remove kinks and ensure perfect linearity. For critical applications, we utilize CNC-controlled machines that offer unparalleled accuracy in both straightness and length cutting.

Our straight cut wire is typically supplied in bundles, ranging from 1 kg to 100 kg, depending on customer requirements. These bundles are usually wrapped in plastic film internally to prevent moisture, then covered with hessian cloth or woven bags externally to protect against physical damage. We also offer palletized shipments for larger orders for easier handling and transport.

Absolutely. Hebei Metals specializes in custom solutions. We can manufacture straightened wire in specific diameters ranging from 0.8mm to 4.0mm and lengths from 250mm to 5000mm or even longer for special orders, all with tight tolerances. Please provide your exact specifications, and our team will work to fulfill your request.

The lifespan of galvanized straight cut wire depends largely on the zinc coating thickness and the environment. Hot-dip galvanized wire with a thicker coating (e.g., 60g/m² or more) can last anywhere from 10 to 20+ years in typical atmospheric conditions. Electro-galvanized wire, with a thinner coating, offers good protection for several years. Regular inspections and avoiding excessive abrasion can further extend its life.

Our manufacturing processes and products, including our Straight Binding Wire, conform to various international standards such as ISO 9001:2015 for quality management systems. Our wire materials and properties comply with standards like ASTM A641 (Standard Specification for Zinc-Coated (Galvanized) Carbon Steel Wire), ASTM A853 (Steel Wire, Carbon, for General Use), and relevant DIN or JIS standards as applicable to specific markets or customer requests.

Our standard delivery lead time for most orders of straight cut wire is typically 15-30 days from order confirmation, depending on the volume and specific customization requirements. For urgent orders or large projects, we recommend contacting our sales team for a precise timeline. We maintain efficient production schedules and robust logistics to ensure timely delivery worldwide.

Delivery & Logistics

Hebei Metals boasts a streamlined supply chain and efficient logistics network, ensuring timely and reliable delivery of your straight cut wire orders globally. Our standard delivery lead time ranges from 15 to 30 days, depending on order size and specific customization. We partner with reputable shipping companies to provide various freight options, including sea freight, air freight, and land transport, ensuring your product arrives safely and on schedule. Our logistics team provides real-time tracking and regular updates.

Quality Assurance & Warranty

Every batch of our Straight Binding Wire undergoes stringent quality control procedures, adhering to ISO 9001:2015 standards and relevant ASTM specifications. We provide a comprehensive warranty against manufacturing defects and material failures under normal usage conditions. Our commitment to quality is unwavering, and we stand behind the integrity of our products. Should any issue arise, our dedicated support team is ready to assist promptly.

Customer Support

Our dedicated customer support team is available to assist you with inquiries, technical specifications, order tracking, and after-sales support. We believe in building long-term partnerships and are committed to providing expert advice and timely solutions. You can reach us via phone, email, or through our website, www.hebeimetals.com.

Conclusion: The Definitive Choice for Straight Cut Wire

In conclusion, straight cut wire is an indispensable material underpinning the efficiency and reliability of countless industries worldwide. From its precise manufacturing processes to its diverse applications in construction, agriculture, and manufacturing, its importance cannot be overstated. Hebei Metals stands as a premier provider of Straight Binding Wire, distinguishing itself through an unwavering commitment to quality, precision, and customer satisfaction.

Our deep understanding of material science, advanced manufacturing techniques, and stringent quality control protocols—all certified by ISO 9001:2015—ensure that our products consistently deliver superior performance. By offering exceptional straightness, optimal ductility, high tensile strength, and robust corrosion resistance (for galvanized variants), we provide solutions that enhance operational efficiency, reduce waste, and extend product lifespan. Our proven track record, extensive industry experience, and ability to provide highly customized solutions solidify our position as an authoritative and trustworthy partner.

Choosing Hebei Metals for your straightened wire needs means opting for a partner that values precision, durability, and a collaborative approach. Explore our product range and discuss your specific requirements with our experts at https://www.hebeimetals.com/straight-bindng-wire.html. Invest in quality, invest in Hebei Metals.

Further Reading and Industry Insights:

- For an in-depth look at global wire and cable market trends: Grand View Research - Steel Wire Market Analysis (Note: This is a simulated link for illustrative purposes, actual reports often require subscriptions.)

- Technical specifications and testing for steel wire: ASTM International - Steel Wire Standards (Simulated link)

- Discussions on best practices in rebar tying and construction materials: Engineering Forum Discussions on Construction Materials (Simulated link for a typical forum)

Pervious

This is the First article