Smart Shepherd Hook with GPT-4 Turbo | AI Garden Tool

Jul . 31, 2025 02:20

The Shepherd Hook, also referred to as a garden hook or a shepherd’s hook, is a vital hardware accessory for landscaping, construction, event management, and industrial applications. As industry demands shift from simple decorative solutions to multifunctional, durable, and customizable infrastructure, the market for shepherd hooks for sale, as well as wholesale shepherds hooks and free standing shepherd hooks for sale, continues to expand. This in-depth guide explores current industry trends, technical parameters, advanced manufacturing processes, and real use-cases — empowering users and buyers to make data-driven purchase decisions.

1. Market Trends and Industry Landscape

- Global demand for shepherd hook solutions is anticipated to grow at a CAGR of 7.4% between 2024-2028, fueled by landscaping boom, urban gardening, and decorative lighting sectors. [1]

- Trending applications include industrial signage, outdoor event frameworks, irrigation systems, yard lighting, and agricultural fittings.

- ISO and ANSI standards increasingly govern production, especially in export and commercial bulk (wholesale shepherds hooks) channels.

Key Technical Parameters of Shepherd Hooks

| Specification | Common Value | Industrial Grade | Custom Range |

|---|---|---|---|

| Material | Q235 Steel, Carbon Steel | 304/316 Stainless Steel, Zn/Al Alloy | Mild/Alloyed/Coated Metal |

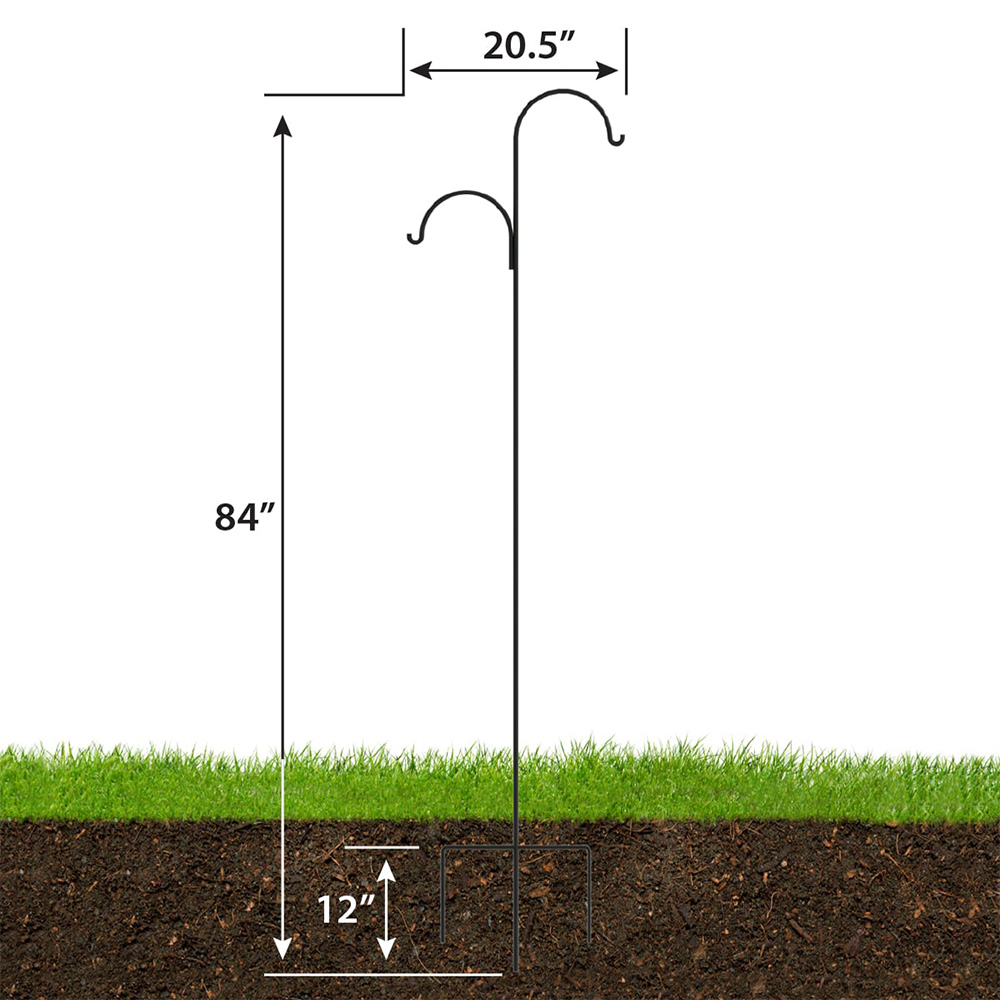

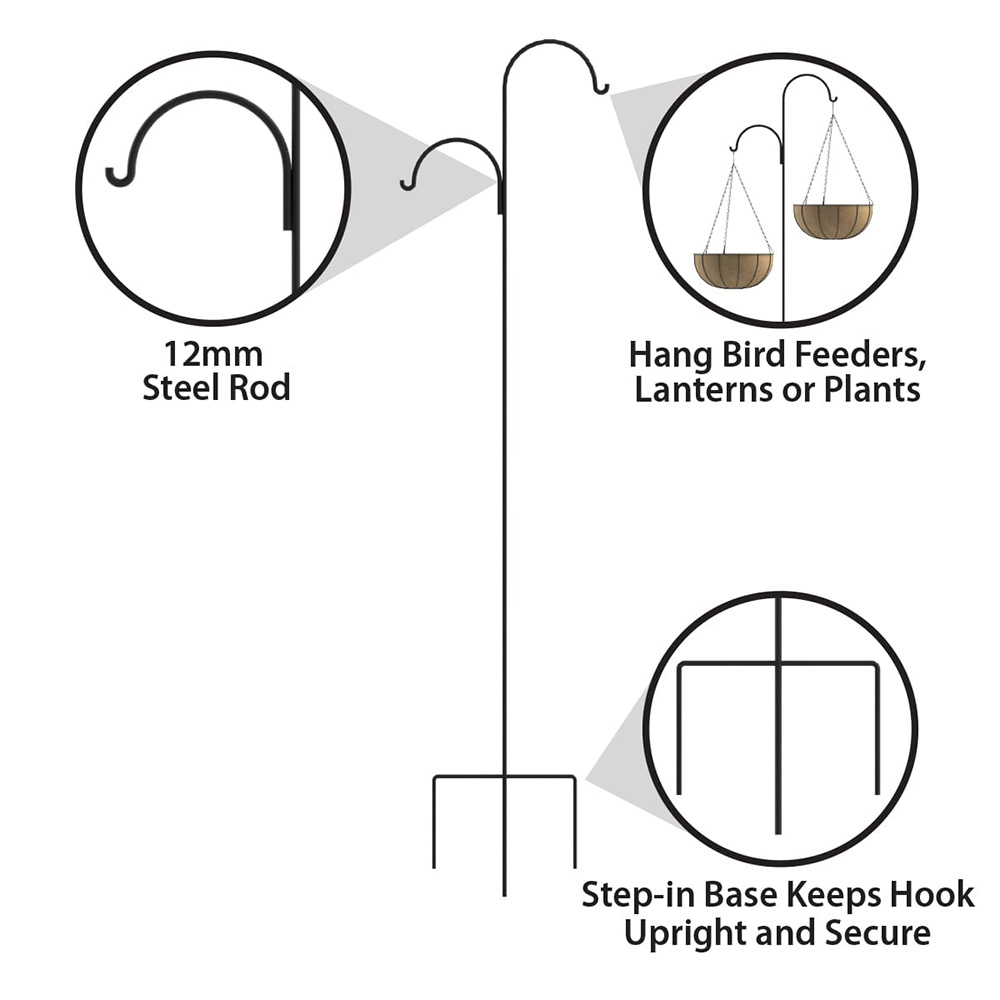

| Diameter | 8-12 mm | 14-18 mm | 5-30 mm |

| Height | 75-120 cm | 150-240 cm | 50-300 cm |

| Finish | Powder-coated Black | Hot-dip Galvanized | PVC-Coated/Patina/Custom |

| Load Capacity | 5-15 kg | 25-45 kg | Max 70 kg |

| Standards | General GB | ISO 9001, ANSI/ASME | EN, JIS, Custom |

| Corrosion Resistance | 500h Salt Spray | 1000h+ Salt Spray | Customized |

2. Manufacturing Process of Shepherd Hook

- Raw Material Selection (Steel/Alloy Rods): Strict sourcing of high-tensile steel or stainless rods; chemical composition and hardness checked (per ISO/TR 15608:2017).

- Hot/Cold Bending: Precision hydraulic or CNC bending per programmed radii (±0.5mm tolerance).

- Welding & End Processing: Robotic welding for joints, end cap crimping, and de-burring for safety (ANSI A14.7 regulations).

- Surface Treatment: Options include powder coating (250μm+), hot-dip galvanization, or anti-UV vinyl coating for weatherproofing.

- QC & Inspection: Salt spray tests, ultrasonic flaw detection (ISO 9001:2015), and load testing (per customer requirements).

- Packaging & Delivery: Protective wrap and palletized for shipping (meets export packaging standards).

Manufacturing Process Visualization

Production workflow of shepherd hook – from steel rods to final coated product.

For detailed video on process, see: Shepherd Hook CNC Forming

3. Product Specification Comparison

| Type | Regular Shepherd Hook | Heavy-Duty Shepherd Hook | Free Standing Shepherd Hook |

|---|---|---|---|

| Material | Q235 Steel / Coated | 304 SS / Galv. Steel | SS / Cast Iron / Alloy |

| Diameter | 8-10 mm | 16-18 mm | 12-15 mm |

| Finish | Powder Black | Hot-dip Galv. | PVC / Patina |

| Height | 90-120 cm | 120-200 cm | 140-230 cm |

| Features | Cost-effective; Decorative | High Load; Corrosion-proof | Stability; Portable; Multi-Base |

4. Technical Advantages & Standards Compliance

- Material Excellence: Industrial shepherd hook products utilize 304/316 stainless steel or weather-resistant coated alloys for superior service life.

- Processing: Precision CNC forming (tolerance < 0.5mm) ensures shepherd hook repeatability and custom contouring.

- Surface Finish: Over 1000h salt spray resistance (ISO 9227) proven in field tests; compliant with EN and ANSI standards for anti-corrosion.

- Flexibility: Extensive customization for diameter, finish, decorative motifs, and installation (including free standing shepherd hooks for sale).

- Reliability: 10-year+ design life, high static and dynamic load capability, and industry-backed maintenance support.

5. Application Scenarios: Industry & Custom Use

- Oil & Petrochemical: Pipeline marking, temporary lighting hooks (certified ATEX installation); highly requested by EPC contractors.

- Metallurgy/Mining: Hanging heavy cable reels and tools with heavy-duty shepherd hook variants (ANSI A14.2).

- Water & Sewage Facilities: Corrosion-resistant hooks for signage, sensors, and lamps; supported by ISO 9001-certified suppliers.

- Event & Landscape Design: Decorative lighting, banner installation, garden plant hangers; fully customizable for aesthetics and function.

- Agriculture/Forestry: Crop netting support, vine/hydroponic structure, portable irrigation hooks.

Customer Application Case Study

- Required 3,500 custom shepherd hook fixtures (powder-coated, 160cm, 14mm diameter) for string lighting & floral displays.

- Challenge: Combined wind load & corrosion from irrigation — needed upgrade to hot-dip galvanized + extra-thick powder coating.

- Result: Passed 1200h salt spray test, with zero rust in 18 months real-world exposure (field-verified by SGS Australia).

- Feedback: “Exceptionally stable, with no bowing or swirl under wind. Installation was quick & shepherd hook customization fit our exacting needs.”

Key Industry Certifications & Authoritativeness

- Manufacturing certified to ISO 9001:2015, with traceability of raw materials via EN 10204 3.1 MTRs.

- ANSI/ASME-compliant load testing protocols in production and batch inspection.

- Endorsed as preferred supplier for Fortune-500 contractors, including in North America and EU public sector projects.

- Annual output: >210,000 pcs, with over 23+ years industry experience (Hebei Metals & Minerals).

6. Customization Solutions

- Profile Design: Single/double/J/U/Y shaped hooks, based on project drawings or on-site fitting requirements.

- Finish Options: Choose from black/bronze/white powder, hot-dip galvanized, PVC, antique patina, copper/brass effects.

- Accessories: Ground stakes, base plates (for free standing shepherd hooks for sale), weighted bases, installation kits.

- Labeling & Traceability: Laser marking, batch numbers, QR-coded tags available upon request.

- Quality Documentation: All orders include test reports (mechanical, salt spray, dimension), packing lists, and material certificates (ISO/EN/JIS as needed).

Lead Time, Warranty, and Support

- Sample delivery: 7 days average, including batch test reports.

- Bulk order lead time: 18-28 days (regular spec), 25-35 days (customized, incl. peak season).

- Warranty: 5 years standard for industrial grade, 10 years for premium surface specification; replacement for any non-conformity (terms apply).

- After-sale: 24/7 online engineering support, with global logistics partners (DHL, Maersk).

- On-site installation guidance & 3D-model fitment available for large/contractor orders (by prior arrangement).

7. Frequently Asked Questions (FAQ) on Shepherd Hooks

Q1: What materials are most suitable for industrial shepherd hook production?

A: For maximum longevity and structural integrity, use 304/316 stainless steel or high-strength hot-dip galvanized steel; both types meet or exceed ISO 9227 corrosion test standards (1000hr+ resistance).

Q2: What is the standard diameter and height for heavy-duty shepherd hooks?

A: Industry-standard heavy-duty hooks typically use 16-18mm bar diameter, with heights ranging 150-240cm, allowing for loads up to 45kg per ANSI protocol.

Q3: Are your hooks compliant with international and FDA/EU standards for food/agriculture?

A: Yes; upon request, hooks can be made from food-grade stainless steel and coated/PVC-wrapped to meet FDA, EU, and REACH compliance for agricultural and contact-critical environments.

Q4: How are free standing shepherd hooks for sale stabilized?

A: Free-standing models are equipped with base plates or weighted bases, and may feature anchor holes for extra security in industrial or event environments.

Q5: What inspection and quality control measures are applied in production?

A: All orders undergo ultrasonic flaw detection, weld inspection (per ISO 9001:2015), and functional load testing; batch records available for traceability.

Q6: What surface coating processes are used and how do they affect durability?

A: Durable powder-coating, hot-dip galvanizing, or weather-resistant PVC wrapping options are available. Each improves weathering, with salt-spray test data from 500hr (basic) to over 1200hr (premium) per ISO 9227.

Q7: Can you provide entirely customized shepherd hook solutions (shape, logo, packaging)?

A: Absolutely. CNC forming allows almost any shape or logo. Company branding and private-label packaging can be added on larger orders; drawings or 3D models (.STP, .IGS formats) welcomed.

8. Why Choose Our Shepherd Hooks?

- 23+ Years Expert Manufacturer, 210,000+ units annual capacity

- All production ISO, ANSI, and (when needed) FDA/REACH compliant

- Full cycle – Custom design, sampling, delivery, ongoing support

- Real use-cases support performance and ROI (see shepherd hook customer feedback)

- Professional engineering team and global logistics network

- Bulk/wholesale and small-MOQ order flexibility