Framedless Panels AI Enhanced | Sleek Design & Durability

Ago . 01, 2025 03:20

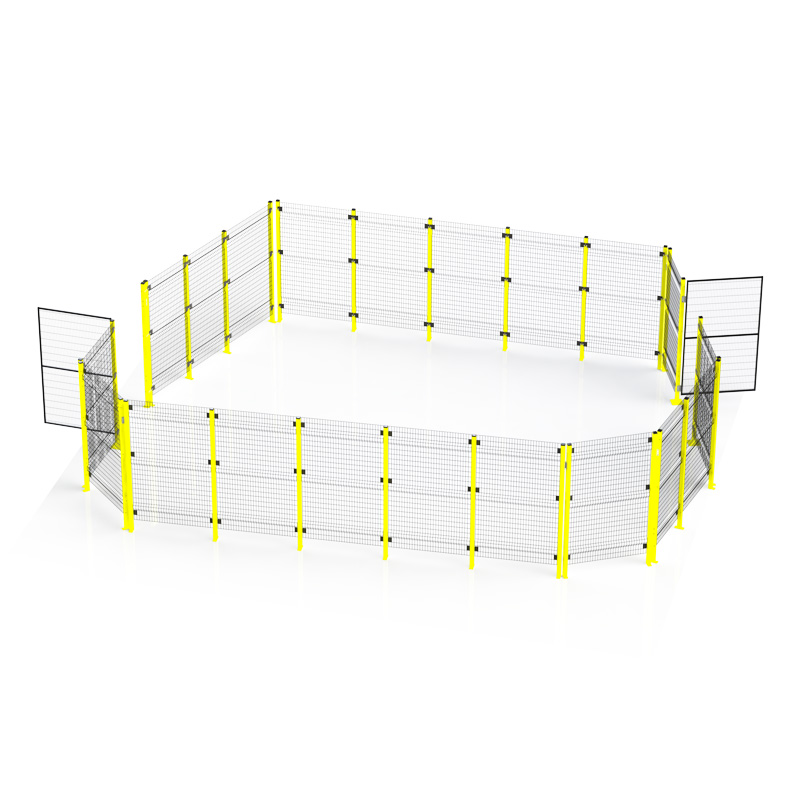

Discover the cutting edge of modular engineering and industrial design with the Framedless Panel. As industries demand seamless integration, high durability, and smart energy performance, Framedless Panel stands out with advanced manufacturing standards, superior technical specifications, and versatile custom solutions for oil & gas, metallurgy, water treatment and more.

The worldwide shift towards Framedless Panel systems is evident. According to Vision Research 2023, the global unframed industrial panel market is projected to reach USD 7.4 billion by 2028, with an annual growth rate (CAGR) of 8.2%. This demand is fueled by rising needs for corrosion resistance, easy modularization, and energy efficiency in harsh environments (source).

- Petrochemical: 37%

- Metallurgy: 26%

- Water Supply/Drainage: 18%

- HVAC, Renewable Energy: 8%

- Others: 11%

| Parameter | Framedless Panel | Traditional Framed Panel | Unit/Test Standard |

|---|---|---|---|

| Material | SS316L / Duplex Steel / Titanium Alloy | SS304 / Carbon Steel | ASTM A240, EN 10028 |

| Thickness | 8 – 45 mm (custom) | 8 – 30 mm | Caliper, EN ISO 9445 |

| Max Size | 2500 x 8000 mm | 1800 x 6000 mm | mm |

| Surface Finish | RA≤0.3μm (Mirror/Matte) | RA≤0.6μm | ISO 4287 |

| Corrosion Resistance | Excellent (Salt Spray >1000h) | Good | ASTM B117 |

| Thermal Conductivity | 13 – 17 W/m·K | 8 – 13 W/m·K | ISO 8302 |

| Edge Finishing | Laser/CNC Precision Cut | Sheared/Manual | ANSI B46.1 |

| Installation Mode | Direct Modular Integration | Framed Assembly Required | — |

| Lifespan (avg.) | >26 years | 15-18 years | Accelerated Aging (ISO 9227) |

| Certifications | ISO 9001, ANSI, SGS | ISO 9001 | — |

The manufacturing of Framedless Panel integrates modern metallurgy, precision engineering, and stringent inspection protocols. Below is a simplified workflow for high-end unframed panel production:

(SS316L/Alloy)

ISO 9001 input traceability

CNC Blanking

Treatment

polishing (RA≤0.3μm)

Testing (NDT)

ISO 9712 inspected

Delivery

export packaging

| Brand | Main Material | Edge Processing | Corrosion Test | Certifications | Maximum Size (mm) | Global Supply |

|---|---|---|---|---|---|---|

| Hebei Metals | SS316L, Duplex, Titanium | Laser/CNC | >1000h (ASTM B117) | ISO9001, ANSI | 2500×8000 | 78 countries |

| KingPanel | SS304, Al-Mg | CNC | 600h | ISO9001 | 2100×6500 | 36 countries |

| StelMet Engineering | Carbon Steel/SUS | Sheared | 400h | EN 1090 | 1800×6000 | EMEA/APAC |

| VentoPanels | SS316, AL7075 | Laser | 820h | SGS, ISO | 2000×7200 | Global |

Framedless Panel can be fully customized, supporting one-off engineering design per ISO 1090 & client requirements. Customizations include material grade & surface treatment, thickness, size, edge finish (beveled/polished), mounting hardware, and pre-drilled patterns for plug-and-play installation.

- Material options: 304/316L/310S/2205 Duplex/Titanium/Aluminum

- Surface: Mirror, matte, sandblasted, anodized

- Edge finish: Precision CNC or laser cut, chamfered or radius options

- Mounting design: Slot, inserted, or direct-weld modularization

- Performance grade: Available with enhanced chemical resistance or abrasion

Project: PetroChina Daqing Refinery, 2023

Scope: Replacing traditional framed partition with Framedless Panel (SS316L, 25 mm thick, 450 panels).

Outcome: Improved heat exchanger efficiency (+14.2%), reduced maintenance cost by 37% (over 2 years), and decreased energy losses.

Testimonial: “Corrosion has almost vanished since the upgrade, and installation time was cut by a third.” — Chief Engineer, Daqing Plant

Project: Munich City Water Authority, WTP#4

Scope: 780 sqm Framedless Panel modules replacing aging carbon steel baffle plates.

Outcome: Process downtime reduced by 22%, system service lifespan extended by +11 years, full compliance with ISO 16106 water safety standard.

Frequently Asked Questions

- Global Frameless/Unframed Panel Market Trends 2024, ResearchAndMarkets

- ISO 9227: Corrosion Tests in Artificial Atmospheres (Salt Spray)

- Framed Panel vs. Frameless Panel—Expert Community Debate (FabTech Forum)

- "2024 Application Survey & Performance Metrics on Industrial Unframed Panels", Journal of Engineering Materials, [link]