-

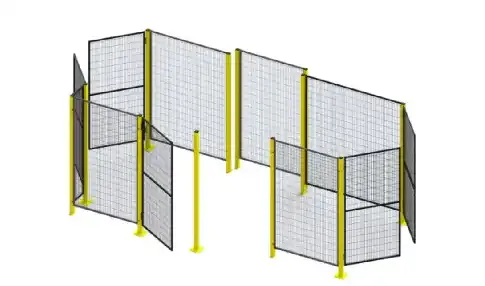

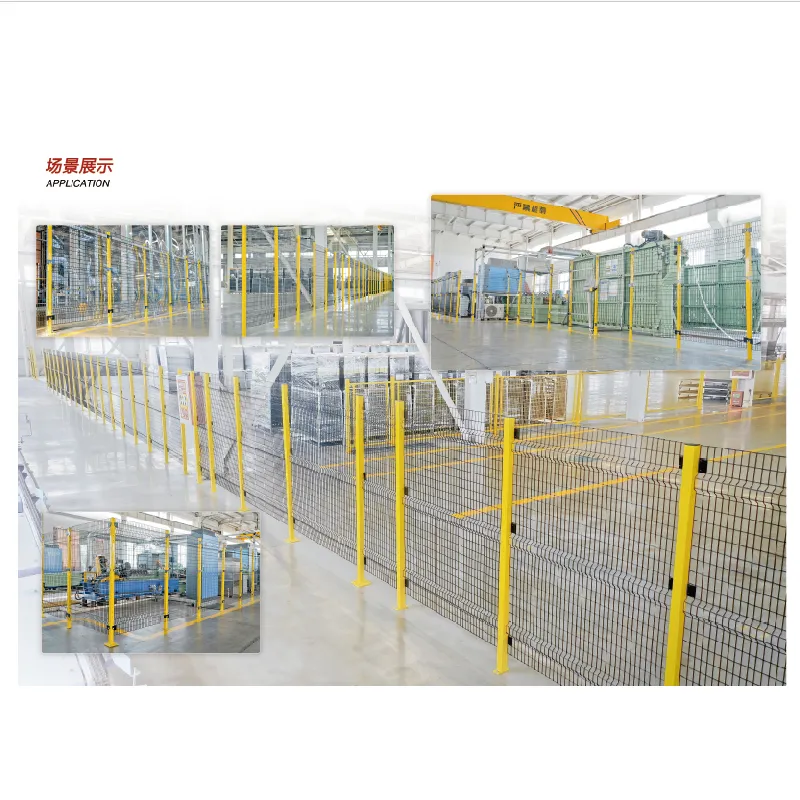

Con una gamma completa di componenti e accessori standard, il sistema MetalTec-Fence può aiutare a risolvere la maggior parte dei problemi di salute e sicurezza sul posto di lavoro.

-

Questa gamma completa di prodotti è sicura, semplice ed economica.

Descrizione

- La natura modulare della protezione dei macchinari MetalTec-Fence consente infinite configurazioni ed è adatta a molte applicazioni.

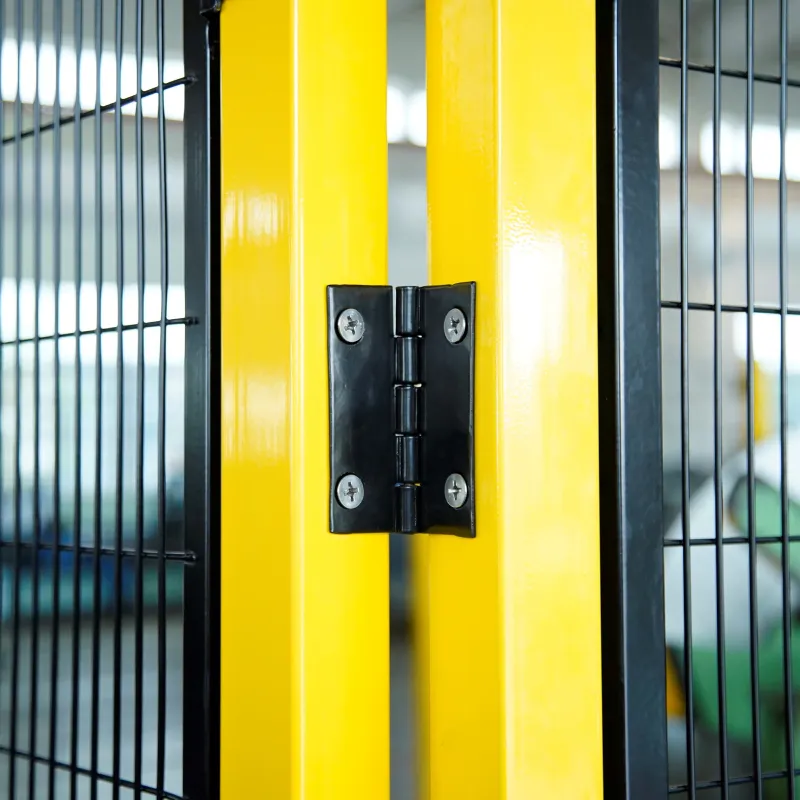

- Si tratta di un sistema di recinzione di sicurezza facile da montare che fornisce una chiara separazione tra lavoratori, macchinari e veicoli, proteggendo sia gli operatori che le attrezzature da lesioni o danni.

Vantaggio

-

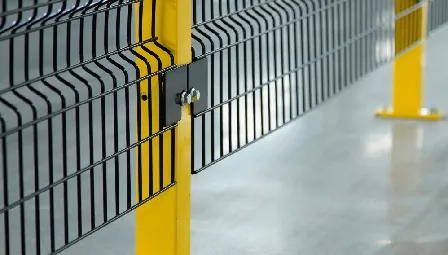

Easy&Quick—Assembly: With a comprehensive range of standard components and Post&Welded base with pre-drilled holes, our MetalTec can be easly and queckly assembled.

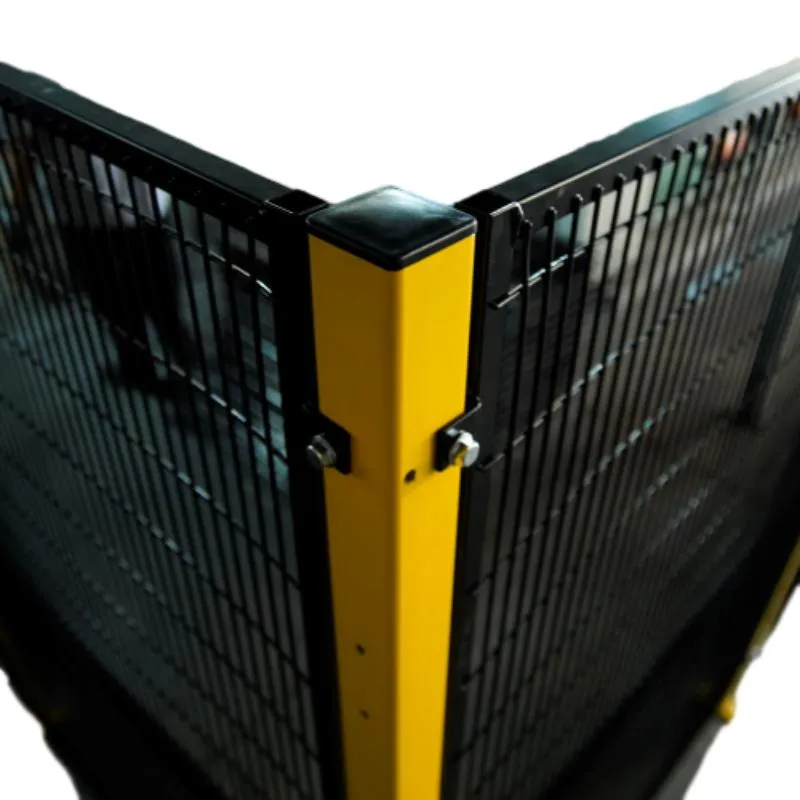

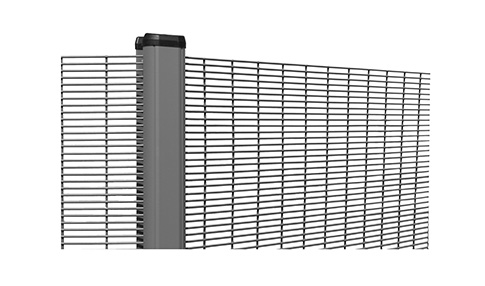

- Anti-arrampicata: i fili verticali esterni limitano gli appigli e scoraggiano efficacemente l'arrampicata.

- Visibilità: Le feritoie verticali e la finitura verniciata nera garantiscono un'ottima visibilità del macchinario attraverso i pannelli in rete metallica.

- Taglio arbitrario: se necessario, i pannelli possono anche essere tagliati a misura o in altezza sul posto e rifiniti con il kit di taglio.

Tabella dei parametri

| DESCRIZIONE |

PART # |

DESCRIZIONE | PARTE # |

|

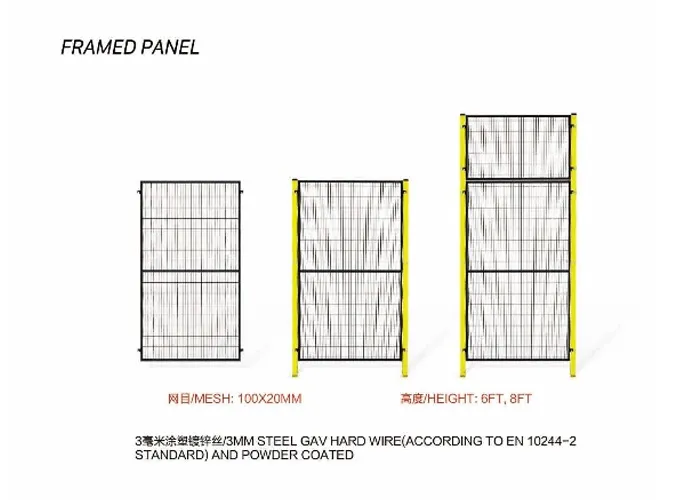

PANNELLO CON CORNICE 200 X 600 VERNICIATO NERO RAL9005 |

FP200X600 |

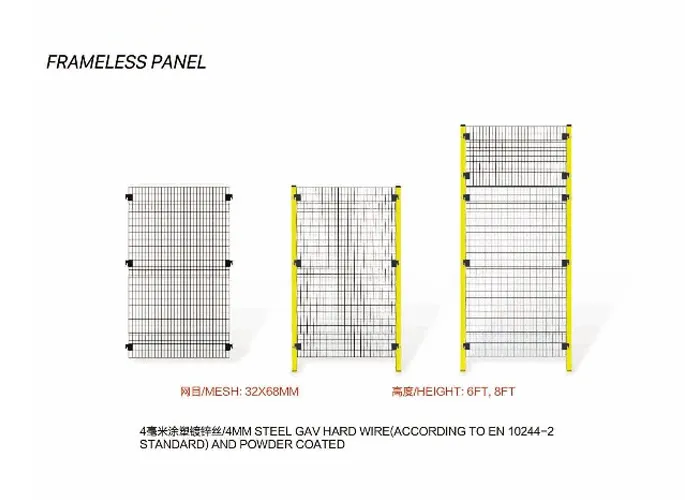

UNFRAMED PANEL, 300 X 600, PAINTED RAL9005 BLACK |

UP300X600 |

|

FRAMED PANEL, 300 X 600, PAINTED RAL9005 BLACK |

FP300X600 |

UNFRAMED PANEL, 500 X 600, PAINTED RAL9005 BLACK |

UP500X600 |

|

FRAMED PANEL, 700 X 600, PAINTED RAL9005 BLACK |

FP700X600 |

UNFRAMED PANEL, 800 X600, PAINTED RAL9005 BLACK |

UP800X600 |

|

FRAMED PANEL, 800 X 600, PAINTED RAL9005 BLACK |

FP800X600 |

UNFRAMED PANEL, 1000 X 600, PAINTED RAL9005 BLACK |

UP1000X600 |

|

PANNELLO CON CORNICE 1000 X 600 VERNICIATO NERO RAL9005 |

FP1000X600 |

UNFRAMED PANEL, 1200 X600, PAINTED RAL9005 BLACK |

UP1200X600 |

|

FRAMED PANEL, 1200 X600, PAINTED RAL9005 BLACK |

FP1200X600 |

UNFRAMED PANEL, 1500 X 600, PAINTED RAL9005 BLACK |

UP1500X600 |

|

FRAMED PANEL, 1500 X 600, PAINTED RAL9005 BLACK |

FP1500X600 |

UNFRAMED PANEL, 1800 X 600, PAINTED RAL9005 BLACK |

UP1800X600 |

|

FRAMED PANEL, 200 X 1688, PAINTED RAL9005 BLACK |

FP200X1688 |

UNFRAMED PANEL, 2400 X600, PAINTED RAL9005 BLACK |

UP2400X600 |

|

FRAMED PANEL, 300 X 1688, PAINTED RAL9005 BLACK |

FP300X1688 |

UNFRAMED PANEL, 300 X 1688, PAINTED RAL9005 BLACK |

UP300X1688 |

|

FRAMED PANEL, 700 X 1688, PAINTED RAL9005 BLACK |

FP700X1688 |

UNFRAMED PANEL, 500 X 1688, PAINTED RAL9005 BLACK |

UP500X1688 |

|

FRAMED PANEL, 800 X 16B8, PAINTED RAL9005 BLACK |

FP800X1688 |

UNFRAMED PANEL, 800 X 1688, PAINTED RAL9005 BLACK |

UP800X1688 |

|

FRAMED PANEL, 1000 X 1688, PAINTED RAL9005 BLACK |

FP1000X1688 |

UNFRAMED PANEL, 1000 X1688, PAINTED RAL9005 BLACK |

UP1000X1688 |

|

FRAMED PANEL, 1200 X 1688, PAINTED RAL9005 BLACK |

FP1200X1688 |

PANNELLO SENZA CORNICE 1200 X 1688 VERNICIATO NERO RAL9005 |

UP1200X1688 |

|

FRAMED PANEL, 1500 X 1688, PAINTED RAL9005 BLACK |

FP1500X1688 |

UNFRAMED PANEL, 1500 X 1688, PAINTED RAL9005 BLACK |

UP1500X1688 |

|

UNFRAMED PANEL, 1800 X 1688, PAINTED RAL9005 BLACK |

UP1800X1688 |

||

|

UNFRAMED PANEL, 2400 X1688, PAINTED RAL9005 BLACK |

UP2400X1688 |

Types of Machine Guarding Fences

Machine guarding fences are essential for ensuring workplace safety, particularly in environments where heavy machinery is in operation. These fences protect workers from potential hazards such as moving parts, flying debris, and other mechanical risks. Here’s a look at the main types of machine-guarding fences used in industrial settings:

Welded Wire Mesh Fences

Welded wire mesh fences are one of the most common types of machine guarding. Made from high-quality steel wire, these fences are durable, flexible, and easy to install. The welded mesh structure allows for visibility into the machine's operation, ensuring that operators can monitor the process while remaining safe. They are ideal for general-purpose machine guarding, particularly in environments where light visibility and access control are important.

Solid Panel Fences

Solid panel machine guarding fences offer complete containment around machines, providing a higher level of protection. Made from materials like steel or plastic, these fences prevent any material or debris from escaping the machine’s area. Solid panels are ideal for machines with higher-risk operations, such as heavy-duty equipment or high-speed machinery, where full containment is required to prevent accidents.

Perimeter Guarding Fences

Perimeter-guarding fences are designed to protect workers from a wider area, often surrounding entire machine zones or workspaces. These fences are typically taller and provide a secure boundary to restrict access to dangerous areas. They are particularly useful for large machinery or automated systems where workers need to be kept at a safe distance.

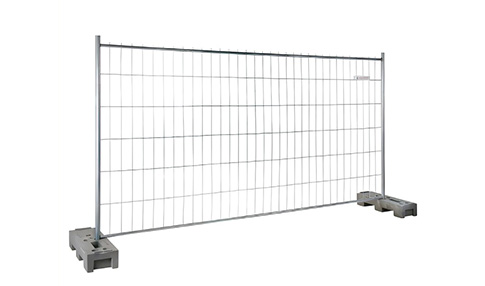

Adjustable or Modular Fences

Adjustable machine guarding fences provide flexibility in terms of installation and modification. These modular systems can be adapted to fit different machine sizes and configurations, making them ideal for facilities with dynamic production lines or changing equipment setups. They offer ease of maintenance and scalability while maintaining high safety standards.

Each type of machine guarding fence serves a unique function, ensuring both the safety of workers and compliance with industry standards. Choosing the right type depends on the specific needs of the machinery and the level of protection required.

The Role of Machine Guarding Fences in Workplace Safety

In today's industrial environments, safeguarding workers from potential hazards has become a paramount concern. One of the pivotal components of an effective workplace safety strategy is the implementation of machine-guarding fences. These protective barriers play a critical role in ensuring employee safety by preventing accidental contact with dangerous machinery.

Machine guarding fences are designed to create a physical barrier around hazardous equipment, thereby limiting access to unauthorized personnel. By establishing a clear demarcation between operational areas and employee workspaces, these fences significantly reduce the risk of injuries caused by moving parts or operational machinery. Moreover, they serve as a visual cue, warning workers of potential risks in their proximity and encouraging them to adhere to safety protocols.

Beyond enhancing worker safety, machine-guarding fences are also beneficial for compliance with occupational safety regulations. Regulatory bodies stipulate that organizations must take adequate measures to protect their workers from workplace dangers. Installing effective machine-guarding fences not only meets these legal requirements but also demonstrates a company's commitment to a safety-first culture.

Furthermore, the design and material of machine guarding fences are critical considerations. They should be made of durable materials that can withstand daily wear and tear while maintaining their structural integrity. Additionally, incorporating transparent panels can provide visibility for monitoring machinery operations without compromising safety.

In conclusion, machine-guarding fences are an essential element of workplace safety strategies. By providing a secure barrier against hazardous equipment, ensuring compliance with health regulations, and fostering a culture of safety, these fences play a pivotal role in protecting employees in various industrial settings. Investing in quality machine-guarding fences is an investment in the overall safety and well-being of the workforce.