Exploring the 26% Performance Improvement of 2014 Leaf Spring Technology

Nov . 08, 2024 11:52

The Evolution and Applications of 26% 201% 4% Leaf Springs

Leaf springs are a type of suspension system widely used in various vehicles, particularly in trucks, trailers, and some SUVs. Their design and functionality have evolved over the years, with advances in materials and engineering playing a crucial role. In this article, we will explore the concept of leaf springs, focusing on the significance of the 26% 201% 4% configuration and its applications in modern automotive engineering.

Understanding Leaf Springs

Leaf springs are made up of several flat, elongated pieces of spring steel. These pieces, known as leaves, are stacked on top of one another to create an arc shape. When a load is applied to the spring, the leaves flex, allowing for shock absorption and stability. This design provides the vehicle with a smooth ride over uneven terrains and contributes to load-bearing capacity.

The configuration of a leaf spring can vary widely, and it can be tailored to meet specific requirements depending on the vehicle's intended use. One such configuration is the 26% 201% 4% metric, which highlights the potential for customization in leaf spring design.

The 26% 201% 4% Configuration

An essential aspect of leaf springs like the 26% 201% 4% model is the distribution of stress and weight. The numbers indicate dimensions related to the spring's material composition and performance characteristics. The percentage values can be interpreted as follows

- 26% may refer to the thickness or a specific alloy composition that improves the spring's durability and flexibility. This particular measurement could signify a higher resistance to deformation and a better load-bearing capacity. - 201%, possibly representing a tensile strength or load rating, indicates the spring's capability to handle significant weight without yielding. This is crucial for vehicles that transport heavy materials or require extra support for stability. - 4% could denote the spring's overall height or the number of leaves in the stack, affecting both ride comfort and handling characteristics.

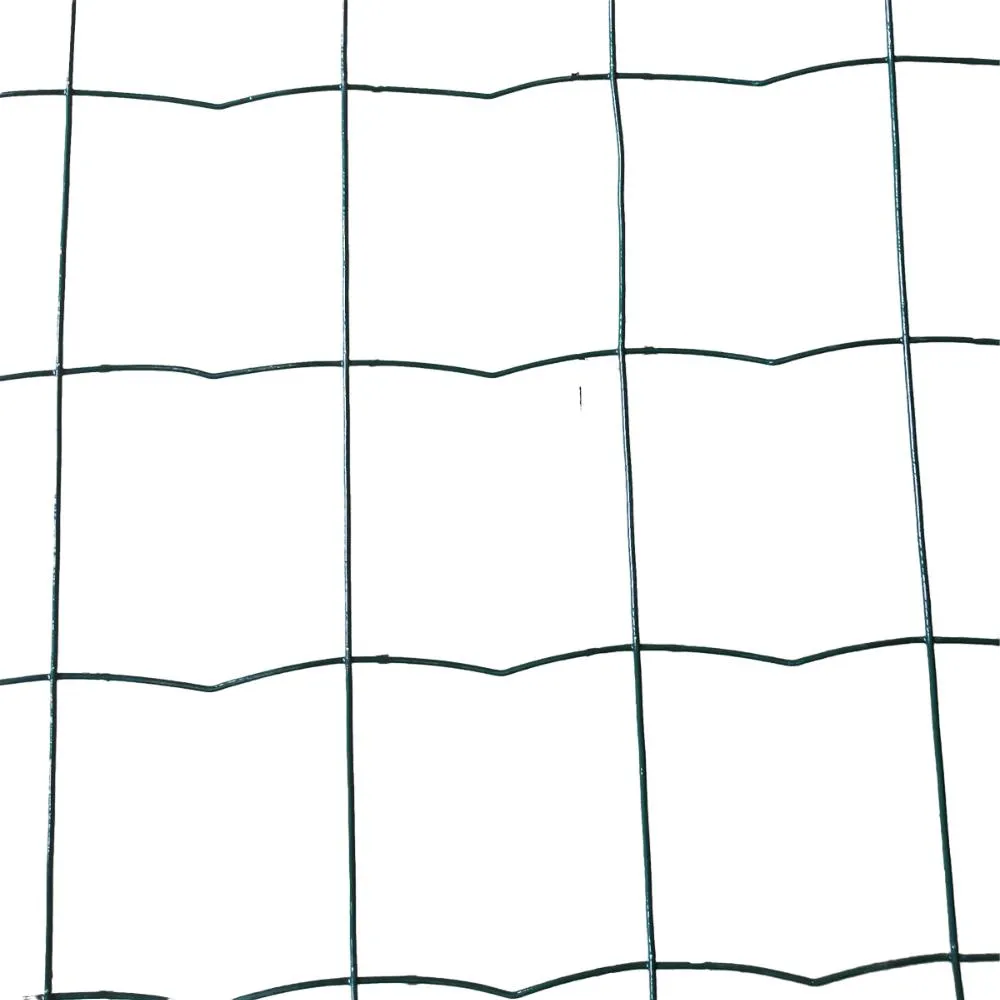

26 1 4 leaf spring

Together, these specifications ensure that the leaf spring can perform efficiently under various conditions. Whether driving on rugged terrain or navigating urban landscapes, a well-engineered leaf spring can provide optimum support and comfort.

Applications in Modern Vehicles

Leaf springs have found a place in many aspects of contemporary vehicle design, particularly in heavy-duty applications. They are common in commercial trucks, where heavy payloads are a daily reality. The robust nature of leaf springs, exemplified by configurations like 26% 201% 4%, allows for optimal weight distribution and handling without compromising safety.

In addition to trucks, leaf springs are also employed in off-road vehicles and trailers. Their ability to absorb shocks makes them ideal for navigating bumpy roads and rough terrains. Furthermore, they are often utilized in retrofitting older vehicles to enhance their load-carrying abilities while maintaining ride quality.

The introduction of advanced materials, such as composites and high-strength steels, has improved the performance and longevity of modern leaf springs. Manufacturers are continually researching and developing new designs that offer even greater customization opportunities, further expanding the applications of leaf springs in various sectors of the automotive industry.

Conclusion

The 26% 201% 4% leaf spring configuration exemplifies the ongoing innovations in suspension technology. As vehicles become increasingly sophisticated, the need for reliable and efficient suspension systems becomes paramount. Leaf springs, with their versatility and strength, continue to play a vital role in transporting goods and people safely. As we further explore materials and design, the future of leaf springs promises enhanced performance, efficiency, and safety in the automotive world.