High-Quality 2% Coil Roofing Nails for Durable Roofing Solutions

Out . 18, 2024 15:38

Understanding 2% Coil Roofing Nails A Comprehensive Guide

When it comes to roofing, selecting the right materials is crucial for ensuring the durability and longevity of a roof. Among the various tools and materials used in roofing, nails play a significant role. One type that often comes up in discussions about roofing materials is the 2% coil roofing nail. In this article, we will explore what 2% coil roofing nails are, their advantages, application methods, and other key features that make them a preferred choice among roofing professionals.

What are 2% Coil Roofing Nails?

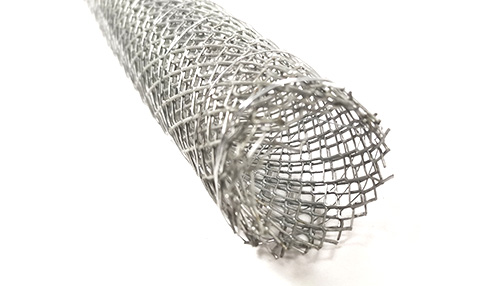

Coil roofing nails are fasteners commonly used in roofing projects due to their efficiency and effectiveness. These nails are usually housed in a coiled format, allowing them to be fed automatically into nail guns. This is where the “2%” designation comes in - it typically refers to the composition or certain performance characteristics of the nails, suggesting that a small percentage might be attributed to specific additives that enhance their performance (this could include corrosion resistance or improved strength).

Advantages of Using 2% Coil Roofing Nails

1. Efficiency One of the main benefits of using coil roofing nails is the time saved during installation. The coiled design allows for a quick reload into a nail gun, making the nailing process faster. This can be particularly advantageous for large roofing projects where time is of the essence.

2. Consistent Performance These nails are designed to maintain consistent performance across various roofing materials, ensuring secure fastening. Their coating often provides additional protection against rust and corrosion, enhancing the longevity of the roof.

3. Reduced Labor Costs With the efficiency of coil nails, the labor costs associated with roofing projects can be reduced. Fewer men-hours spent on the installation process translates to cost savings, allowing contractors to take on more projects in the same time frame.

4. Versatile Applications 2% coil roofing nails can be used in a variety of applications beyond just roofing, including siding and insulation jobs. This versatility makes them a valuable addition to any contractor’s toolkit.

2 coil roofing nails

Application Methods

Using 2% coil roofing nails typically involves the use of a pneumatic nail gun. Here’s a step-by-step process for effective application

1. Preparation Ensure that the work area is clear and that all necessary safety measures are in place. Wearing appropriate personal protective equipment (PPE) such as goggles and gloves is essential.

2. Loading the Nail Gun Open the nail gun and load the coil of nails according to the manufacturer’s instructions. Make sure they are seated properly to avoid jamming during use.

3. Setting the Depth Adjust the nail depth setting on the gun according to the thickness of the materials being used. This ensures that the nails are driven in at an appropriate depth, providing optimal holding power without damaging the roofing material.

4. Nailing Process Begin nailing at one edge of the roofing area and work your way across. Maintain a consistent distance between nails, usually about 6-8 inches apart, depending on the type of roofing material.

5. Final Inspection After the installation, inspect the roof to ensure that all nails are secure and that there are no exposed fasteners, which could lead to leaks and further issues down the line.

Conclusion

In summary, 2% coil roofing nails are an excellent choice for both professional roofers and DIY enthusiasts. Their efficiency, reliability, and versatility make them a staple in the roofing industry. While it’s important to understand the specific needs of your roofing project and the materials being used, incorporating coil roofing nails can streamline the process and lead to a durable, long-lasting roof. Whether you are tackling a small home project or a large commercial roofing job, these nails can help ensure that the end result meets the high standards that today’s roofing demands.

Unity

Unity Creation

Creation Challenge

Challenge Contribution

Contribution