Related News

High-Quality Coil Nail for Fast and Efficient Nailing Solutions

Jul . 29, 2025 19:40

【Expert Review | 2024 Industry Benchmark Edition】

What is Coil Nail? Definition & Market Overview

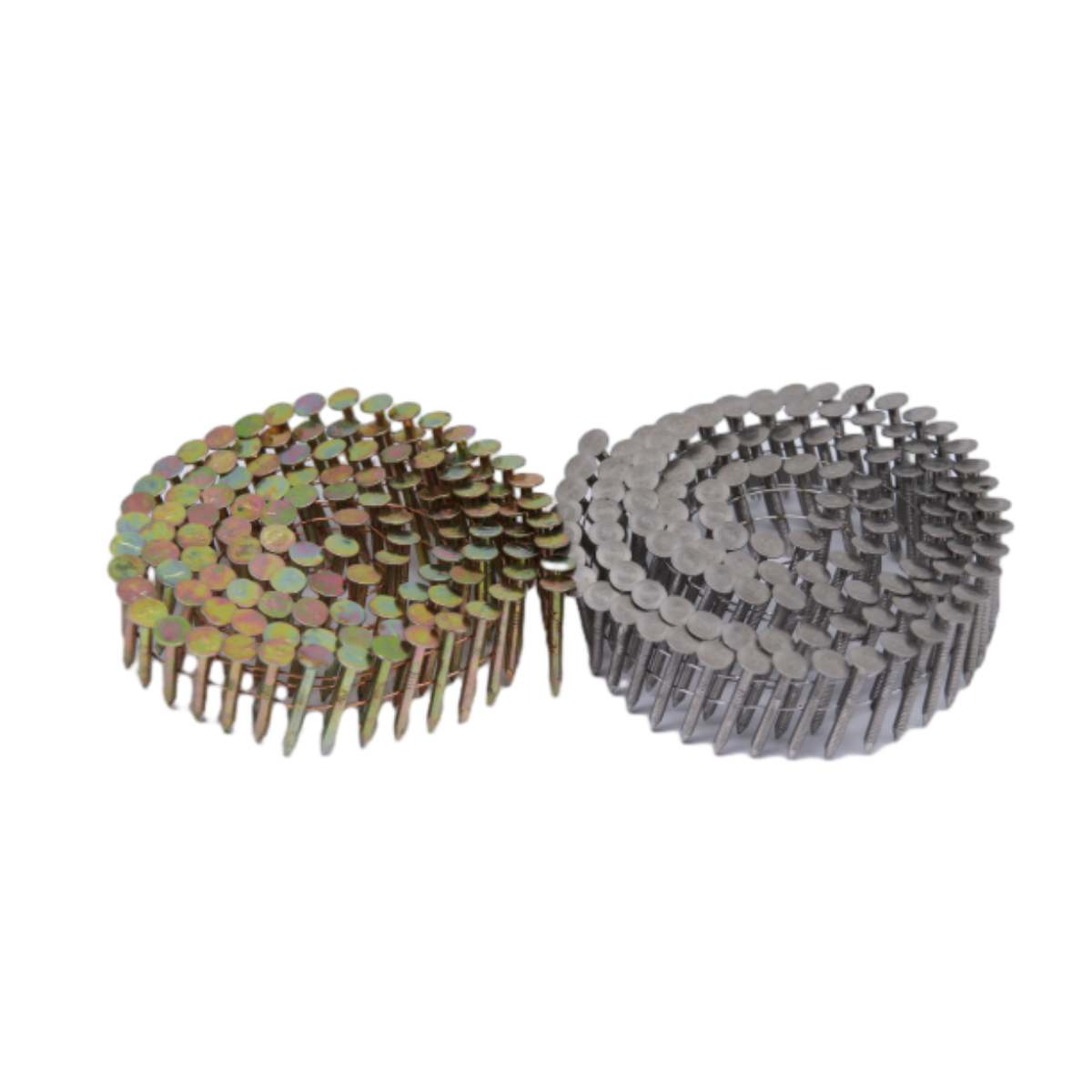

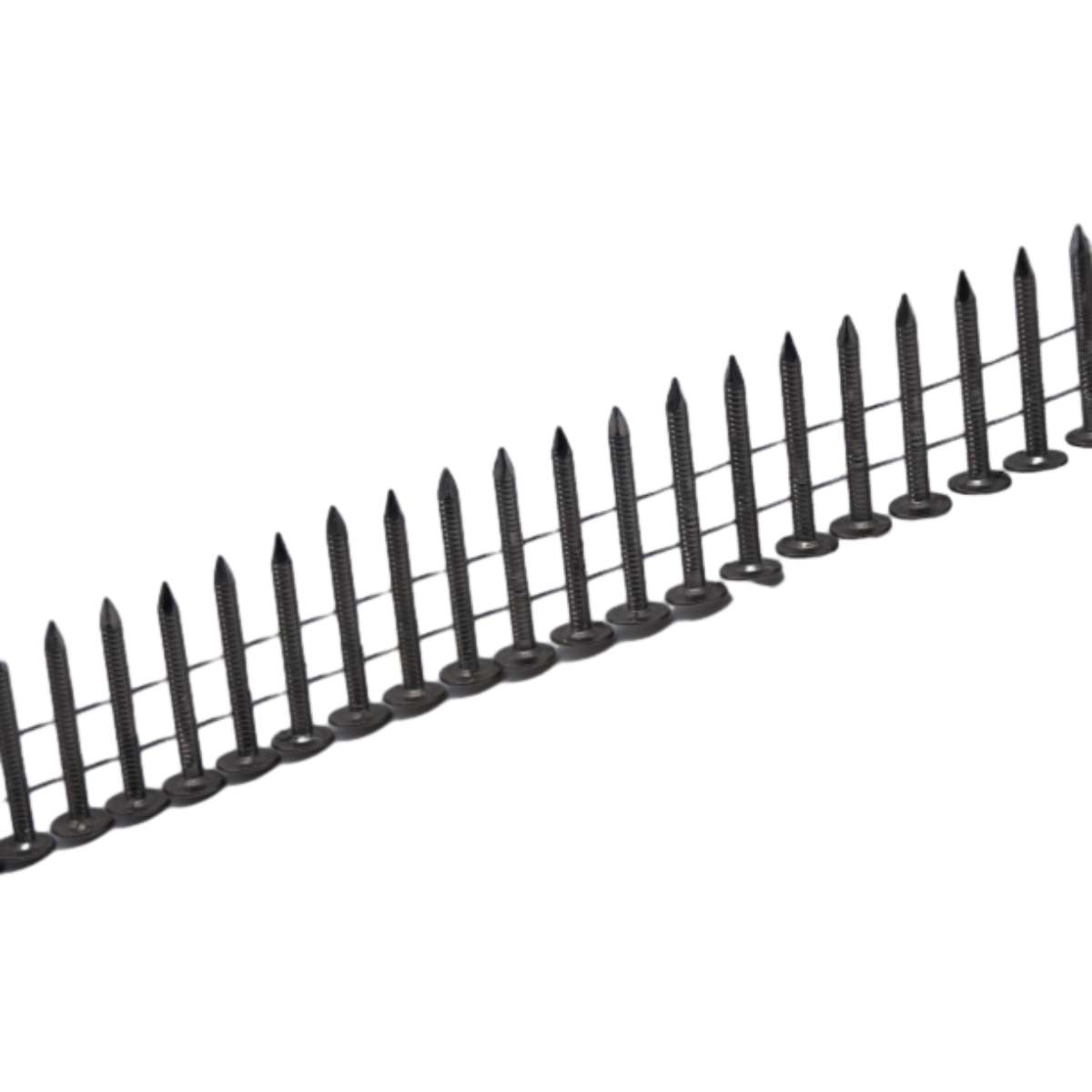

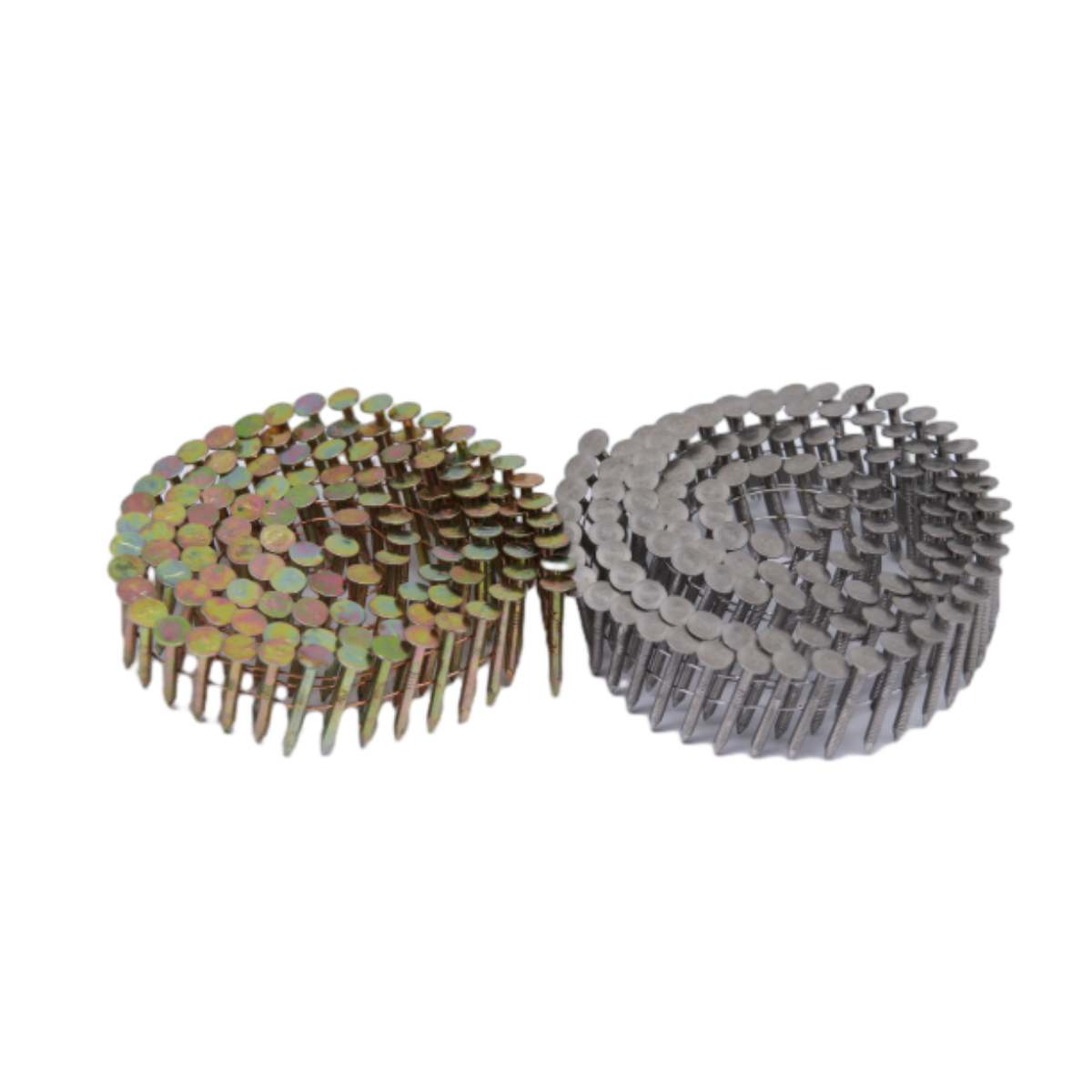

Coil Nail refers to a type of wire nail system wound and collated in a coil format, designed especially for pneumatic or gas-driven nail guns (nailers), supporting rapid and automated fastening in construction, manufacturing, pallets, and packaging industries. The coil design enhances work efficiency and capacity, holding 100–300 nails per coil, compared to traditional stick or bulk nails.

According to MarketsandMarkets 2023: • Global Coil Nail Market valuation in 2023: $2.1 billion USD • CAGR (2023–2028): 5.2% • Key Growth Sectors: Prefab Construction, Automotive Assembly, Pallet & Crating

Coil Nail Technical Parameters Table (2024 Mainstream Types)

| Model/Type | Diameter (mm) | Length (mm) | Shank Type | Material | Coating | Typical Application | Holding Power (N) | Corrosion Resistance Grade | Compliance |

|---|---|---|---|---|---|---|---|---|---|

| CN15EG | 2.1 | 25–50 | Smooth | Q195/Q235 Steel | Electro-galvanized | Pallet, Case | 1450 | ANSI Level 6 | ISO 9001 |

| CN21HD | 2.3 | 32–57 | Ring | Low-carbon Steel | Hot-dip Galv. | Construction | 1860 | Level 9 | ANSI/ASTM F1667 |

| CN28SS | 2.8 | 38–65 | Screw | Stainless 304 | Polished | Outdoor Decking | 2040 | Level 10 | EN 10230-1 |

| CN32HDG | 3.1 | 45–90 | Ring/Screw | Q235 Steel | Hot-dip Galv. | Framing, Subfloor | 2220 | Level 9 | ISO/ANSI |

| CN34ALUM | 2.5 | 32–75 | Ring | Aluminum Alloy | Anodized | Corrosive Env. | 1180 | Level 8 | ISO 9227 |

Manufacturing Process Flow — Coil Nail Production (Step-by-Step)

Standard Process Flow:

- Wire Drawing (Raw Wire→Target Diameter via CNC Drawing Machines)

- Cold Heading (Forming Nail Head Under Pressure, High Precision)

- Shank Forming (Smooth/Ring/Screw/Fine Threaded Surface via Rollers)

- Cutting & Pointing (CNC Cutting, Diamond/Blunt/Chisel Tip)

- Surface Treatment (Electroplating / Hot-dip Galvanization / Powder Coating)

- Collation & Coiling (Welding Nails along Strip & Winding into Coil; Set Angle/Spacing)

- Inspection & Testing (Pull-out, Hardness, Corrosion Resistance per ISO 9227 & ANSI/ASTM F1667)

- Packing & Delivery (Automatic Counting, Custom or Bulk Box Packing)

Click for Video Demo:

Coil Nail Production Video (YouTube)

Technical Flowchart:

Comprehensive Coil Nail manufacturing flow: from wire drawing to coil packaging.

Key Materials:

Q195/Q235 steel, 304/316 Stainless steel, Aluminum alloy (for anti-corrosion)

Manufacturing Modes: CNC cold heading, automated roll threading, high precision collator winding

Testing Standards: ISO 9227 Salt Spray, ASTM F1667, EN 10230-1, ANSI Nail Quality

Manufacturing Modes: CNC cold heading, automated roll threading, high precision collator winding

Testing Standards: ISO 9227 Salt Spray, ASTM F1667, EN 10230-1, ANSI Nail Quality

Industry Trends & Technology Parameters Analysis

Coil Nail vs. Major Manufacturers (Competitive Benchmark Table)

| Manufacturer | Country | Key Material | Custom Options | Tech Standard | Certifications | Annual Output (Tons) | Warranty | ISO/ANSI Compliance |

|---|---|---|---|---|---|---|---|---|

| HEBEI METALS | China | Q195, 304/316SS | Diameter/Length/Finish | ISO 9001, EN 10230-1 | SGS, CE | 25,000 | 2 Years | YES |

| Bostitch (Stanley) | USA | Steel, Galv. | Moderate | ASTM F1667 | UL, ISO | 18,000 | 1.5 Years | YES |

| JITO Fastener | Korea | Low-carbon Steel | Diameter | KS B1016 | K-MARK | 8,000 | 1 Year | Partial |

| MAX Fastening Systems | Japan | Steel, Stainless | Head Shape | JIS B2808 | JIS | 5,500 | 2 Years | YES |

| Global Nail Ltd | Europe | Steel | Basic | EN 14592 | CE | 9,800 | 1 Year | YES |

Custom Coil Nail Solutions & Material Selection Guide

Material Tailoring:

- Q195/Q235 Mild Steel Coil Nail: Low-cost, high tensile, for general construction, palletizing

- 304/316 Stainless Coil Nail: Excellent anti-corrosion, suitable for exterior, stone, highly humid or marine applications

- Aluminum Alloy/Brass Coil Nail: Specialized for chemical industries, non-magnetic and ultra corrosion resistance

- Electro-Galvanized & Hot-Dipped Galvanized: Salt spray > 700 hours, conforms to ISO 9227

- Powder Coated / Epoxy Finish: Color code options, added anti-abrasion layer

- Diameter Range: 1.8mm – 3.8mm; Length: 25mm – 130mm (customizable)

- Head: Flat, countersunk, umbrella (anti-slip/cosmetic)

- Shank: Smooth, ring, screw, fluted

Application Scenarios & Advantages

- Pallet & Crate Manufacturing (Bulk Coil Nail saves 3x loading time vs stick nail, proven in GMA-standard factories)

- Wood Construction/Timber Framing (High holding power, consistent head, meets ANSI subfloor standards)

- Decking & Fencing (Anti-corrosion options, eliminates surface rust for 10+ years in ISO salt-spray test)

- Automotive & HVAC Assembly (Precise, zero jam in high-speed lines; certified by ISO 9001 supply chains)

- PVC/Polyboard & Composite Fastening (Special nails for low expansion/contraction; field tests at -30°C/+60°C)

- Masonry Lath & Siding Installation (Screw-shank coil for superior withdrawal, pass ASTM F1667 pullout)

Certified by Industry Standards

- ISO 9001: Manufacturing Quality Management System

- ISO 9227: Salt spray corrosion resistance accreditation

- ANSI/ASTM F1667: Nail performance & safety testing

- EN 10230-1: Construction fastener compliance (Europe)

- Regular SGS/CE Product Third-party Auditing

Key Service Advantages:

- Fast delivery: Production within 7 days of order confirmation (custom models: 10–14 days)

- Full inspection: 100% batch traceability & online testing report

- Warranty: 2 years performance guarantee. Free technical service & training

- Global support: Overseas warehouses in EU/US, round-the-clock logistics

- OEM/ODM: Custom logo/packing/label for corporate customers

Real Application Cases & Client Feedback

Project 1: Pallet Manufacturing — Largest US Factory, 2.5 million units/year

Used: Coil Nail CN21HD Ring shank, Hot-dip Galv.

Results: Same-shift efficiency up 24%, repair rate halved, end customers reported 99.7% delivery acceptance.

Used: Coil Nail CN21HD Ring shank, Hot-dip Galv.

Results: Same-shift efficiency up 24%, repair rate halved, end customers reported 99.7% delivery acceptance.

Project 2: Decking Contractor (New Zealand, Coastal)

Used: Coil Nail 304 Stainless, Screw Shank

Results: Anti-corrosion reports after 5 years—no rust, no withdrawal, surface sills intact (passed ISO 9227).

Used: Coil Nail 304 Stainless, Screw Shank

Results: Anti-corrosion reports after 5 years—no rust, no withdrawal, surface sills intact (passed ISO 9227).

Project 3: Automotive Cabin Assembly (Germany)

Used: Custom small-diameter, umbrella head Coil Nail

Results: Automation lines run 18 hours/day, less than 0.1% jam rate, annual procurement increased in 2023.

Used: Custom small-diameter, umbrella head Coil Nail

Results: Automation lines run 18 hours/day, less than 0.1% jam rate, annual procurement increased in 2023.

End-user Feedback:

- “Coil configuration saves us at least 30% labor time per shift.” – Mechanized Pallet Factory

- “All batches passed CE/SGS test – crucial for European export.” – Turkish Construction Customer

- “Corrosion resistance is real: No call-backs even in marine decks!” – Australia Building OEM

Professional FAQ (Coil Nail Technology and Industry Terms)

1. What is the optimal material for Coil Nail in outdoor use?

304 or 316 stainless steel provides the best anti-corrosion performance. For budget-conscious applications, hot-dipped galvanized Q195/Q235 steel is also suitable if within ISO 9227-certified environments.

2. How do I select between smooth, ring, or screw shank Coil Nail?

Ring and screw shank offer higher withdrawal resistance (see pull-test graph above), recommended for structural or impact-vibrated assemblies. Smooth is typically for packaging, speed, or low-load applications.

3. What are typical dimensions of industrial Coil Nail?

Diameter: 1.8mm–3.8mm, Length: 25mm–130mm. Custom size options available per project specs.

4. What are standard installation and compatibility benchmarks?

All Coil Nail products comply with ANSI/ASTM F1667, and can be loaded into most pneumatic or cordless coil nailers (Bostitch, MAX, Senco, etc.).

5. Which standards and tests should be requested for quality assurance?

ISO 9001 for production, ISO 9227 for corrosion, ASTM F1667/EN 10230-1 for dimension and mechanical property, plus onsite pull-out/hardness test data.

6. Is custom packaging/logo available for Coil Nail bulk purchase?

Yes, HEBEI METALS offers OEM/ODM—label, branding, and carton design can be matched to client needs.

7. What is the typical product lead time and warranty term?

Standard delivery is as fast as 7 working days; custom parameters may extend to 10–14 days. All Coil Nail batches carry a 2-year warranty covering breakage/corrosion and manufacturing defects.

Order Process, Delivery and Quality Guarantee

- Quotation & Technical Consultation within 24 hours

- Sample dispatch (standard Coil Nail models: 1–2 working days)

- Production cycle: Standard: 5–7 days per batch; Large custom: 10–14 days

- Third-party inspection, complete shipment photos/videos

- 2-year quality warranty; Technical engineer online support

- Exported to 50+ regions with CE/SGS/ISO documentation

Contact & Support

Get your custom Coil Nail solution.

Email: sales@hebeimetals.com Tel/WhatsApp: +86-133-0328-3768

Free technical support, sample test, and order status tracking.

Email: sales@hebeimetals.com Tel/WhatsApp: +86-133-0328-3768

Free technical support, sample test, and order status tracking.

References:

[1] MarketsandMarkets. “Nails and Fasteners Market—By Type, Application, & Region—Global Forecast,” 2023-2028. https://www.marketsandmarkets.com/Market-Reports/nails-fasteners-market-48398528.html

[2] FastenerWorld Magazine: “2024 Coil Nail Market Analysis,” https://www.fastener-world.com

[3] ASTM International. “F1667-22 Standard Specification for Driven Fasteners,” https://www.astm.org/f1667-22.html

[4] Woodworking Network Forum—Coil vs Stick Nail Use Cases, https://www.woodworkingnetwork.com/forums

[1] MarketsandMarkets. “Nails and Fasteners Market—By Type, Application, & Region—Global Forecast,” 2023-2028. https://www.marketsandmarkets.com/Market-Reports/nails-fasteners-market-48398528.html

[2] FastenerWorld Magazine: “2024 Coil Nail Market Analysis,” https://www.fastener-world.com

[3] ASTM International. “F1667-22 Standard Specification for Driven Fasteners,” https://www.astm.org/f1667-22.html

[4] Woodworking Network Forum—Coil vs Stick Nail Use Cases, https://www.woodworkingnetwork.com/forums