Welded Wire Solutions for 1% 2% 36 x 1 x 3 Applications and Beyond

Set . 28, 2024 04:49

The Versatility and Applications of 1% 202% x 1% x 36% Welded Wire

Welded wire has earned its place as an essential material in various industries and applications due to its strength, durability, and adaptability. Among the many types of welded wire, the 1% 202% x 1% x 36% variant stands out, providing unique advantages that cater to a wide spectrum of needs. This article delves into the features, manufacturing process, and applications of this particular type of welded wire.

Understanding 1% 202% x 1% x 36% Welded Wire

To grasp the significance of the 1% 202% x 1% x 36% welded wire, we must first decode the nomenclature. The numbers and percentages primarily relate to the wire's dimensions and material specifications. This specific type of welded wire is crafted using high-quality steel, with each wire strand being meticulously welded at intersections to create a robust grid. The design ensures maximum tensile strength, making it suitable for applications where reliability is paramount.

Manufacturing Process

The production of welded wire involves several key steps. Initially, steel rods are drawn into wire, achieving the desired diameter. The chosen material often undergoes galvanization to enhance corrosion resistance. This step is critical, particularly in outdoor applications or environments exposed to moisture.

Once the wires are prepared, they are arranged in a predetermined grid pattern. The welding process is then employed, where heat is used to fuse the wires at their intersections. This method not only ensures a strong bond but also maintains uniform spacing, which is vital for various applications.

After welding, the wire is typically subjected to a quality inspection process to identify any defects. This ensures that only the highest grade of welded wire is distributed into the market. Final treatments may include coating or painting, depending on the intended use and environment.

Versatile Applications

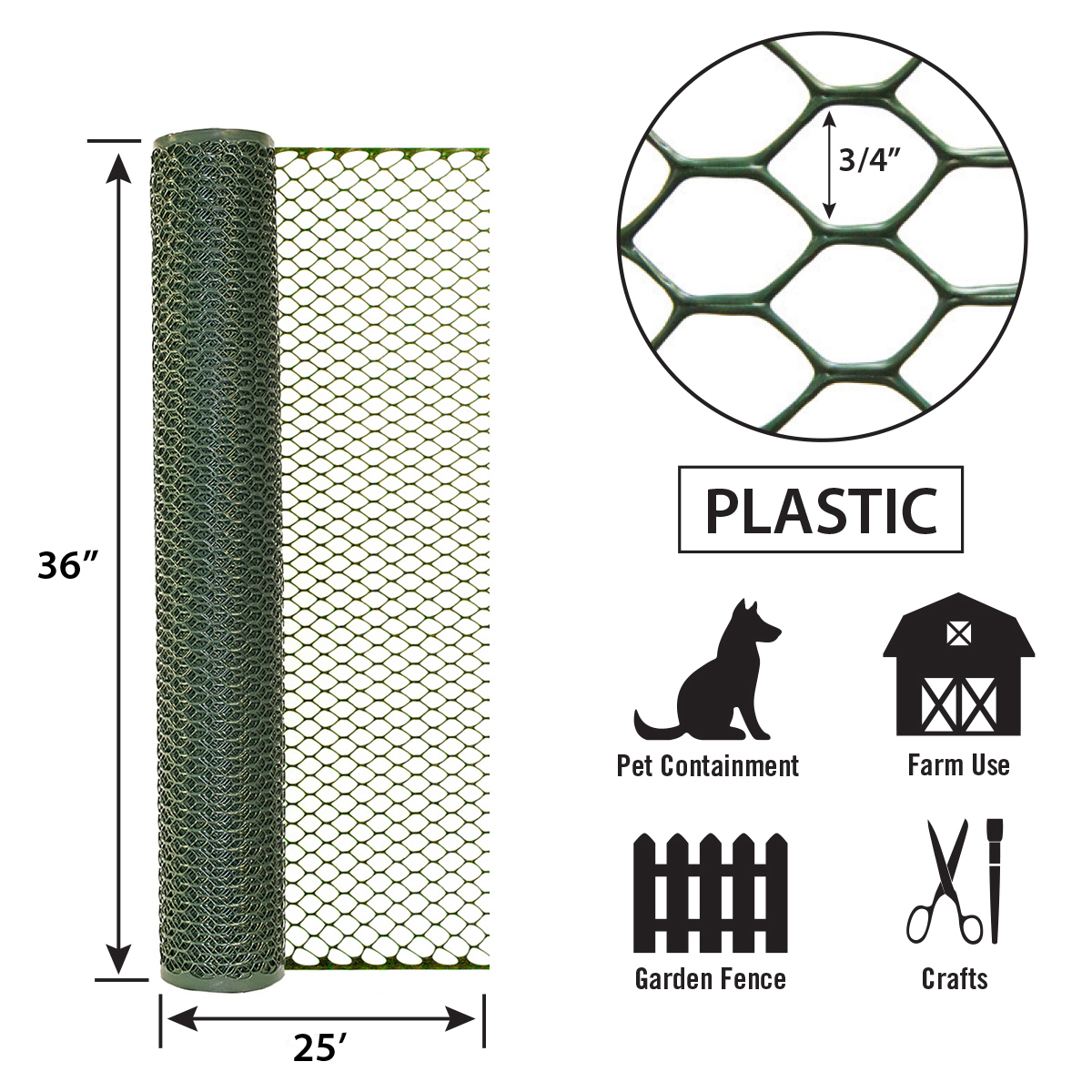

1 2 x 1 x 36 welded wire

1% 202% x 1% x 36% welded wire finds utility in diverse sectors, thanks to its ease of use and reliability. Here are some prominent applications

1. Agricultural Fencing Farmers and agricultural businesses rely on welded wire for fencing livestock and protecting crops. Its strength ensures that it can withstand the pressures exerted by animals while keeping them contained.

2. Construction Industry In construction, welded wire mesh is extensively used in concrete reinforcement. The grid-like structure provides essential support, ensuring that structures remain sturdy and maintain their integrity over time.

3. Industrial Use Many manufacturing environments utilize welded wire for creating secure enclosures or racks. This helps in organizing inventory efficiently and ensuring safety by preventing unauthorized access to certain areas of the facility.

4. Architectural Designs Welded wire is gaining popularity in architectural applications, where it is used for decorative screens, facades, and security barriers. Its aesthetic versatility combined with durability makes it an excellent choice for innovative designs.

5. Home and Garden In residential settings, this type of welded wire can be seen in garden fences, trellises, and plant supports. Gardeners often choose welded wire for its ability to hold up against the elements while providing a clean and polished look.

Conclusion

In conclusion, the 1% 202% x 1% x 36% welded wire is a remarkable product that exemplifies the blend of strength and versatility. Its manufacturing process ensures high-quality output, which translates into dependable performance across multiple sectors—from agriculture to construction, and even personal home projects. The adaptability of welded wire continues to make it a preferred choice for various applications, demonstrating that it is more than just a functional product; it is a vital component in countless projects and industries. As we move forward, the continued innovation in materials and techniques will only enhance the capabilities and applications of welded wire, solidifying its role in modern manufacturing and design.