cement wire

Nov . 15, 2024 05:48

The Importance of Cement Wire in Construction

In the construction industry, the selection of materials is paramount to ensure durability, strength, and safety. Among these materials, cement wire has emerged as a critical component that enhances the structural integrity of various projects. This article delves into the significance of cement wire, its applications, and its role in modern construction practices.

What is Cement Wire?

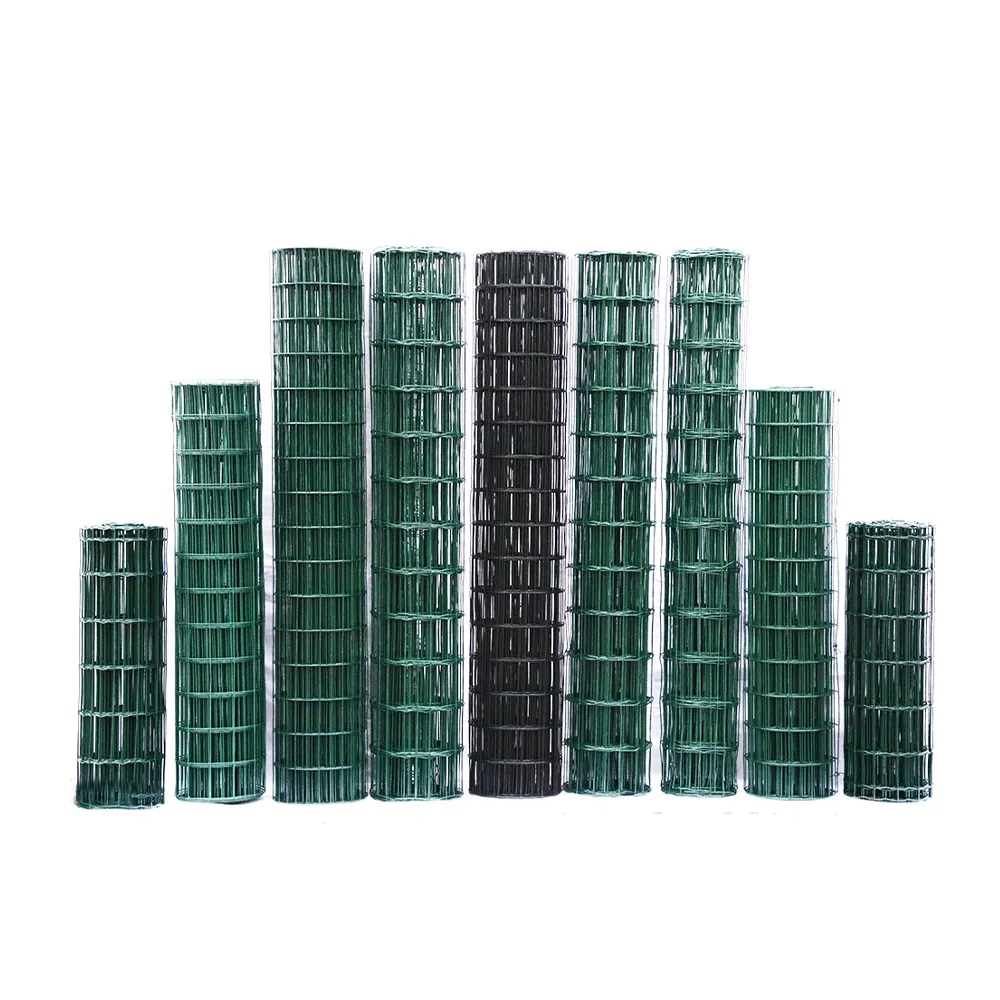

Cement wire, commonly known as wire mesh or concrete wire, is a type of reinforcement material made from steel wire strands that are welded together to form a grid-like pattern. This grid is typically used in conjunction with concrete to provide additional strength and support, distributing loads evenly to prevent cracking and structural failure. The wire is often coated with a layer of protection to increase its resistance to corrosion and ensure its longevity in various environmental conditions.

Applications of Cement Wire

Cement wire is utilized in a wide range of construction applications. One of the most common uses is in the creation of reinforced concrete slabs. By embedding cement wire within the concrete, contractors can significantly enhance the slab's load-bearing capacity, making it ideal for driveways, floors, and other heavy-use areas.

Moreover, cement wire is crucial for forming walls and foundations, where the need for stability and strength is paramount. It is also used in precast concrete components, which are manufactured in a controlled environment and then transported to the construction site. This method reduces construction time and enhances the quality of the finished product.

In addition to these applications, cement wire is often employed in the construction of fencing and barriers, particularly in agricultural and industrial settings. The durable nature of cement wire makes it an excellent choice for enclosing properties, livestock, and farming equipment, providing security and protection.

Advantages of Cement Wire

cement wire

The use of cement wire comes with numerous advantages. First and foremost, it provides exceptional tensile strength, allowing concrete structures to withstand tension forces that would otherwise lead to cracking. This is especially crucial in areas prone to seismic activity or heavy loads.

Secondly, cement wire significantly improves the durability of concrete. By reinforcing it, the risk of deterioration over time is minimized, lengthening the lifespan of structures and reducing the need for maintenance. This not only saves money but also enhances the safety of the built environment.

Furthermore, cement wire is flexible and adaptable; it can be cut and shaped to fit various project requirements. This versatility allows architects and engineers to implement innovative designs without compromising structural integrity.

Challenges and Considerations

Despite its merits, the use of cement wire is not without challenges. One primary concern is the potential for corrosion, especially in environments with high humidity or exposure to saltwater. To mitigate this risk, manufacturers often produce galvanized or epoxy-coated wire, which offers additional protection against rust and degradation.

Additionally, the installation process requires careful attention. Proper spacing and alignment are crucial to ensure maximum effectiveness. Poorly placed cement wire can lead to uneven stress distribution and ultimately compromise the structure’s integrity.

Conclusion

Cement wire plays a vital role in modern construction, providing essential reinforcement that enhances the strength and durability of concrete structures. Its applications range from foundations to fencing, making it a versatile choice for builders and contractors. While challenges such as corrosion and installation precision exist, the benefits of cement wire far outweigh the drawbacks. As the construction industry continues to evolve, cement wire will undoubtedly remain a key material, contributing to safer and more robust infrastructures worldwide.

Unity

Unity Creation

Creation Challenge

Challenge Contribution

Contribution