Coil Nail Manufacturer | Galvanized & Stainless, OEM Bulk

Nov . 10, 2025 14:11Chiodo a spirale is a key solution in the manufacturing industry, specifically within Fabricated metal products and Fastener manufacturing. This article explores how Hebei Minmetals Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Coil Nail Overview

- Benefits & Use Cases of Coil Nail in Fastener manufacturing

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Coil Nail from Hebei Minmetals Co., Ltd.

Coil Nail Overview

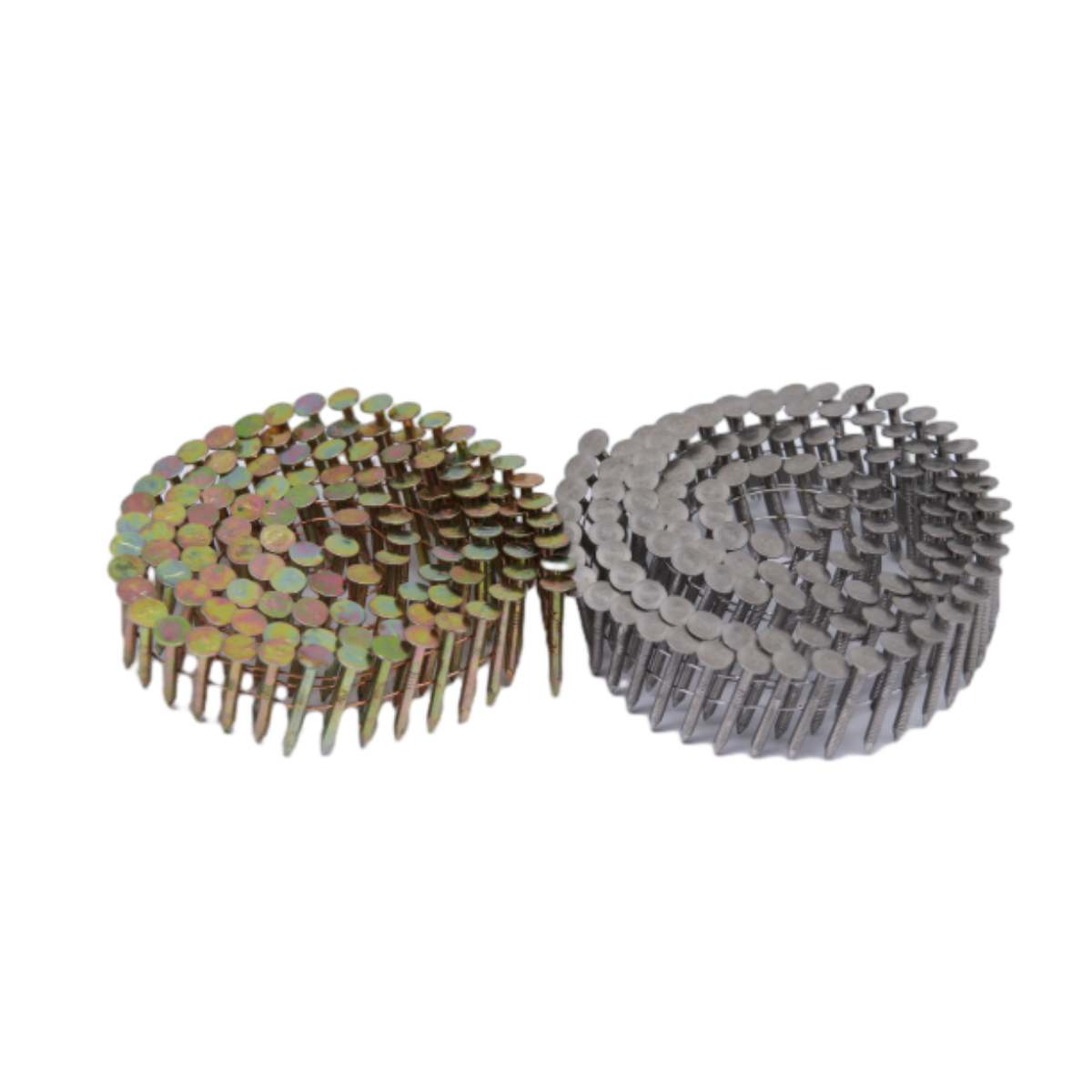

In high-throughput assembly, pallet, roofing, and framing lines, a coil nail is a wire-collated, 15°-angled fastener engineered for pneumatic tools to minimize reloads and maximize uptime. Typical specifications include diameters from 2.0–4.1 mm (approx. 0.079–0.162 in) and lengths from 25–90 mm (1–3-1/2 in) for framing/siding, with roofing coils commonly at 19–45 mm (3/4–1-3/4 in). Options span smooth, ring, and screw shanks; finishes such as bright, electro-galvanized, hot-dip galvanized, or stainless (304/316); and full-round heads with 200–400 nails per coil depending on nail size and application.

From a manufacturing perspective, consistent point geometry, shank hardness, and coating weight are critical to drive performance and pull-out values. Reputable producers validate to common benchmarks such as ASTM F1667-equivalent dimensional and material expectations, conduct bend, drive, and salt-spray tests, and ensure compatibility with mainstream 15° coil nailers. Hebei Minmetals Co., Ltd. supplies coil nails with tight tolerances, reliable collation welds, and application-matched coatings to meet the demands of Fabricated metal products and Fastener manufacturing, backed by robust process control and documentation. Explore specifications and options on the product page: https://www.hebeimetals.com/coil-nail.html.

Benefits & Use Cases of Chiodo a spirale in Fastener manufacturing

In fastener-driven production, coil nails are the go-to for pallets and crating, offsite modular construction, siding/fencing, roofing, and light framing—anywhere sustained fastening speed and consistent set depth are vital. The coiled format means fewer reloads, enabling longer intervals between stops on high-speed lines. Wire collation stabilizes feed and reduces misfires, especially when paired with precision point geometry that lowers wood splitting and improves holding power in softwoods, hardwoods, and engineered substrates.

- Applications: pallet stringers and deck boards, export crates, sheathing and subfloor, shingles (roofing coil nails), fencing pickets/rails, and furniture frames.

- Advantages: tight diameter and length tolerances, consistent coating weights for corrosion zones, optimized shank patterns (ring/screw) for enhanced withdrawal resistance, and compatibility with major 15° pneumatic nailers.

- Hebei Minmetals Co., Ltd.: flexible OEM/private-label, broad spec coverage (bright, EG, HDG, SS), and dependable lead times that help B2B buyers stabilize inventory and throughput.

Cost, Maintenance & User Experience

Total cost of ownership for a coil nail extends beyond price per thousand. Fewer jams, fewer reloads, and longer tool life materially impact ROI. A simple model: if a line experiences five jams per shift at two minutes each, and improved collation quality reduces that to two jams, you recover six minutes per shift; across three lines and 250 production days, that’s 75 hours of regained capacity. Add to that the extended service life from appropriate coatings (HDG or stainless for outdoor/coastal) and the savings from reduced rework and call-backs, and the ROI compounds.

Fabricated metal products customers—especially pallet and crate manufacturers—report steadier feed, uniform clinching, and predictable set depth when using high-consistency coils. Best practices to preserve performance include storing coils dry in original packaging, using FIFO to maintain coating integrity, and following tool OEM guidelines (air quality/pressure, driver blade wear). Hebei Minmetals Co., Ltd. supports users with application-matched specs and documentation so procurement and production teams can jointly optimize cost, uptime, and quality.

Sustainability & Market Trends in manufacturing

Sustainability continues to shape sourcing in fasteners: buyers increasingly request recycled-content steel, lower-impact coatings, and documentation to support LCA/EPD submissions. Regulations and customer requirements favor REACH/RoHS-aligned chemistries, optimized zinc usage, and responsible wastewater and energy management during galvanizing. At the same time, e-commerce and modular construction are driving demand for pallets, crating, and offsite assembly—expanding the market for high-quality coil nails that can run reliably on automated and semi-automated lines.

Hebei Minmetals Co., Ltd. positions its coil nail portfolio for these trends with process discipline, material traceability, and options that support corrosion resistance without over-specifying. The company emphasizes efficient resource use, eco-conscious packaging, and quality systems that reduce scrap and rework—practical sustainability that aligns with B2B procurement goals. As factories scale automation, consistent coil quality from a trusted supplier becomes a strategic lever for both environmental and operational performance.

Conclusion on Coil Nail from Hebei Minmetals Co., Ltd.

For B2B decision makers in manufacturing, a coil nail that feeds smoothly, drives consistently, and resists corrosion is essential to throughput and quality. Hebei Minmetals Co., Ltd. delivers this balance with precise tolerances, application-specific coatings, and reliable supply—value that reduces downtime and total cost of ownership. If you’re optimizing fastener performance across pallet, roofing, siding, or modular lines, partner with a supplier built for industrial demands.

- Coil Nail remains a proven, high-efficiency fastener for Fabricated metal products and Fastener manufacturing.

- Hebei Minmetals Co., Ltd. is a dependable source for quality, consistency, and service.

- Strong CTA: Contact us: email: marketing@hebeimetals.com — Visit our website: https://www.hebeimetals.com