High-Precision CNC Spindle Motors for Machining & Engraving

Ago . 27, 2025 02:00Understanding Industrial Spindles: A Core Component in Modern Engineering

In the intricate world of industrial machinery, the Spindle stands as a critical component, fundamental to the operation of a vast array of equipment ranging from machine tools to rotating process machinery. At its core, a Spindle is a rotating shaft that serves to transmit torque, support rotating elements, or act as a pivotal axis for rotational motion. Its design, material, and manufacturing precision directly dictate the performance, accuracy, and longevity of the entire system it serves. This comprehensive guide delves into the technical aspects, applications, and strategic considerations for selecting and implementing high-quality Spindle solutions in demanding B2B environments.

The industrial landscape is constantly evolving, driven by demands for higher efficiency, greater precision, and extended service life. Current industry trends emphasize the development of Spindles with enhanced material properties, superior surface finishes, and integrated monitoring systems for predictive maintenance. The push towards Industry 4.0 and smart manufacturing necessitates components that can withstand increasingly rigorous operational parameters while providing reliable performance data. Manufacturers are also focusing on optimizing Spindle designs for specific applications, incorporating advanced heat treatment processes, and utilizing sophisticated computational fluid dynamics (CFD) and finite element analysis (FEA) to predict and improve performance under stress.

The Meticulous Process Flow of Spindle Manufacturing

The production of a high-performance Spindle is a multi-stage, precision-intensive process that combines advanced metallurgical science with state-of-the-art machining and quality control. Every step is crucial to ensure the final product meets stringent operational demands.

Key Manufacturing Steps:

- Material Selection and Preparation: High-grade alloy steels such as 40Cr, 42CrMo, or Stainless Steel (e.g., SS304, SS316) are typically chosen based on the application's requirements for strength, toughness, corrosion resistance, and heat treatment response. Materials undergo strict chemical composition analysis and non-destructive testing (NDT) to ensure purity and absence of defects.

- Forging or Casting: Depending on the Spindle's size, complexity, and required mechanical properties, the initial shape is formed. Forging enhances grain structure, improving strength and fatigue resistance, while casting allows for more complex geometries in larger components. This stage lays the foundation for material integrity.

- Rough Machining: The forged or cast blank undergoes initial machining (turning, milling) to remove excess material and bring the component closer to its final dimensions. Tolerances are loose at this stage.

- Heat Treatment: A critical phase involving processes like quenching, tempering, and nitriding or carburizing. This enhances surface hardness, wear resistance, and core strength. For instance, case hardening can achieve surface hardness of HRC 58-62 while maintaining a tough core.

- Precision CNC Machining: Following heat treatment, the Spindle undergoes advanced CNC (Computer Numerical Control) machining. This includes precision turning, grinding, and often honing or lapping to achieve extremely tight dimensional tolerances, geometric accuracy (e.g., runout of less than 0.005mm), and superior surface finish (Ra 0.4 µm or better).

- Surface Treatment (Optional): For specific applications, coatings like hard chrome plating, nickel plating, or specialized ceramic coatings may be applied to further enhance corrosion resistance, wear resistance, or reduce friction.

- Quality Control and Testing: Each Spindle undergoes rigorous testing. This includes dimensional inspection (CMM), hardness testing, ultrasonic testing for internal defects, magnetic particle inspection for surface cracks, and dynamic balancing to minimize vibration. Products comply with international standards such as ISO 9001, ANSI B16.5, ASTM, and DIN, ensuring reliability and interoperability.

- Final Assembly and Packaging: After passing all tests, the Spindle is meticulously cleaned, lubricated, and packaged to prevent damage during transit and storage.

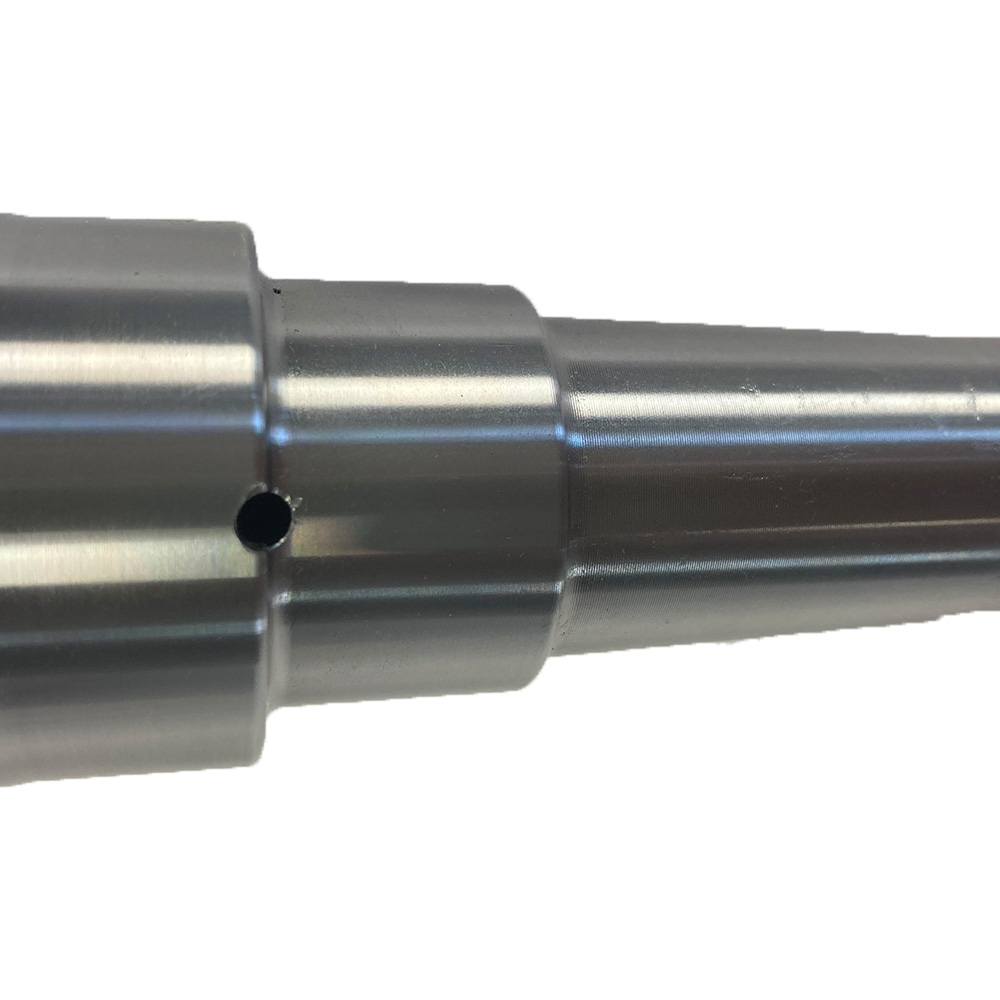

Fig 1: Illustrative example of a Spindle component during a machining stage.

This meticulous process guarantees a service life often exceeding 10-15 years under proper operating conditions and maintenance. In industries like petrochemicals, metallurgy, and water supply & drainage, the advantages are palpable: enhanced energy saving through reduced friction and optimized flow dynamics, and superior corrosion resistance, ensuring long-term operational integrity in harsh environments.

Technical Specifications and Parameters of Advanced Spindles

The performance of a Spindle is quantified by a range of critical technical specifications, which are vital for engineers and procurement specialists to consider. These parameters ensure compatibility, optimize performance, and guarantee safety within complex systems. Below is a comprehensive table outlining typical specifications for industrial Spindles designed for heavy-duty applications.

Fig 2: Close-up of a precision-machined Spindle surface.

These specifications are not merely numbers; they represent the culmination of rigorous engineering and manufacturing excellence, ensuring that each Spindle delivers optimal performance and reliability in its intended application.

Diverse Application Scenarios and Target Industries

The versatility and critical function of the Spindle make it indispensable across a multitude of industrial sectors. Its application spans from high-speed precision tools to heavy-duty process machinery, each demanding specific characteristics from the Spindle component.

Key Target Industries and Applications:

- Petrochemical Industry: Spindles are crucial components in various pumps, compressors, and agitators used for oil and gas extraction, refining, and chemical processing. They must withstand corrosive media, high pressures, and extreme temperatures, often manufactured from materials like SS316 or Duplex stainless steels.

- Metallurgy and Mining: In steel mills, rolling mills, and mining equipment, Spindles are found in heavy-duty gearboxes, crushers, and material handling systems. These applications demand exceptional strength, impact resistance, and wear characteristics to cope with abrasive materials and heavy loads.

- Water Supply & Drainage: Essential for large-scale pumps in municipal water treatment plants, irrigation systems, and wastewater management. Here, the emphasis is on corrosion resistance, reliability for continuous operation, and efficient power transmission.

- Power Generation: Used in turbines (steam, gas, hydro), generators, and auxiliary pumps. These Spindles operate at high speeds and temperatures, requiring superior material stability, dynamic balancing, and fatigue strength.

- Marine and Shipbuilding: In propeller shafts, steering gears, and auxiliary marine engines, Spindles face harsh saline environments and constant vibration, necessitating excellent corrosion resistance and robust mechanical properties.

- Heavy Machinery & Construction: For excavators, cranes, and large industrial mixers, Spindles provide rotational support and power transmission, requiring high torque capacity and durability.

Fig 3: A Spindle as part of a robust industrial pump assembly.

In each of these scenarios, the Spindle is not just a rotating shaft; it is a precisely engineered component critical to the system's efficiency, safety, and operational lifespan. Its design must be intrinsically linked to the environmental and mechanical stresses of its specific application.

Technical Advantages of Our Spindle Solutions

Our commitment to engineering excellence translates into significant technical advantages for our industrial Spindle products, designed to deliver unparalleled performance and reliability in the most demanding environments.

- Superior Material Integrity: We utilize only premium-grade alloy steels and stainless steels, rigorously selected for their specific mechanical properties and resistance to environmental factors. Our materials undergo advanced heat treatment processes, ensuring optimal hardness, ductility, and fatigue strength, far exceeding industry averages.

- Precision Machining Excellence: Employing state-of-the-art CNC machining centers, our manufacturing achieves exceptionally tight tolerances (e.g., IT5-IT7) and superior surface finishes (Ra ≤ 0.4 µm). This precision minimizes friction, reduces wear on mating components like bearings and seals, and contributes to overall system efficiency and energy saving.

- Enhanced Durability and Service Life: Through optimized metallurgical structure and precise manufacturing, our Spindles exhibit exceptional resistance to wear, abrasion, and fatigue. This translates into extended operational lifespans, significantly reducing maintenance frequency and total cost of ownership (TCO). Our products are engineered for a service life of 10-15 years, often outperforming competitors.

- Advanced Corrosion Resistance: For applications in corrosive environments (e.g., chemical processing, marine), we offer Spindles manufactured from high-performance stainless steels (SS304, SS316, Duplex grades) or with specialized protective coatings, ensuring long-term integrity against chemical attack and oxidation.

- Optimized Dynamic Performance: Each Spindle undergoes meticulous dynamic balancing to minimize vibration and ensure smooth, stable rotation even at high speeds. This reduces noise, lowers stress on ancillary components, and enhances the precision of the overall machinery.

- Comprehensive Quality Assurance: Our adherence to ISO 9001 quality management systems, alongside specific industry standards like API 610 for centrifugal pumps or ANSI B16.5 for flange components, ensures every Spindle meets the highest benchmarks for quality and reliability.

Fig 4: Engineering diagram showcasing the intricate dimensions and features of a specialized Spindle.

These advantages collectively contribute to a higher return on investment for our clients by enhancing operational efficiency, reducing downtime, and extending the operational life of their critical industrial assets.

Vendor Comparison: Choosing the Right Spindle Supplier

Selecting a reliable Spindle supplier is paramount for ensuring the long-term performance and efficiency of industrial operations. A detailed comparison beyond just price is essential, focusing on quality, customization capabilities, and post-sales support.

Fig 5: Rigorous quality control measures ensure every Spindle meets the highest standards.

Our distinct advantages in material quality, manufacturing precision, and comprehensive support ensure that our clients receive a superior Spindle that contributes significantly to their operational success and peace of mind.

Customized Solutions for Unique Industrial Demands

Recognizing that off-the-shelf solutions often fall short of meeting the precise requirements of highly specialized industrial applications, we excel in providing fully customized Spindle solutions. Our engineering team collaborates closely with clients to understand their unique operational parameters, environmental challenges, and performance expectations.

Our customization capabilities include:

- Material Specification: Tailoring the alloy steel or stainless steel grade to perfectly match resistance to corrosion, high temperature, or specific chemical agents. This includes exotic alloys for extreme conditions.

- Design Modification: Adapting dimensions, bore configurations, flange types, keyways, and mounting interfaces to seamlessly integrate with existing machinery or new designs.

- Surface Treatments and Coatings: Applying specialized coatings like hard chrome, tungsten carbide, or ceramic overlays to enhance wear resistance, reduce friction, or improve specific environmental resilience.

- Heat Treatment Regimes: Developing specific heat treatment protocols to achieve optimal hardness profiles, core toughness, and fatigue strength for unique load conditions.

- Performance Optimization: Utilizing advanced simulation tools (FEA, CFD) to optimize Spindle design for specific rotational speeds, torque loads, and vibration characteristics, ensuring peak performance and longevity.

Our extensive experience and state-of-the-art facilities allow us to turn complex engineering challenges into robust, reliable, and cost-effective Spindle solutions.

Application Case Studies: Proving Our Expertise

Our commitment to quality and custom engineering has resulted in successful deployments across diverse industries. These case studies highlight our capability to deliver high-performance Spindle solutions for critical applications.

Case Study 1: High-Pressure Pump Spindle for Offshore Oil Rig

Challenge: An offshore oil and gas operator required a replacement Spindle for a critical high-pressure injection pump. The original Spindle failed prematurely due to a combination of abrasive media, high operating pressure (150 bar), and a highly corrosive saline environment, leading to frequent downtime and significant operational losses.

Solution: We engineered a custom Spindle from Super Duplex Stainless Steel (UNS S32750), known for its exceptional corrosion and erosion resistance. The design included a specialized surface hardening process and a precision ground finish (Ra 0.2 µm) to withstand abrasive particle ingress and minimize friction. Dynamic balancing was performed to ISO 1940-1 G2.5 for high-speed stability.

Outcome: The new Spindle has been in continuous operation for over 4 years without any signs of wear or degradation, tripling the service life of the previous component. The client reported a 25% reduction in maintenance costs for that pump unit and significantly improved operational reliability.

Fig 6: A Spindle designed for extreme marine and offshore conditions.

Case Study 2: Large Agitator Spindle for Chemical Reactor

Challenge: A leading chemical manufacturer required a very long (6-meter) Spindle for a new reactor agitator. The challenge was maintaining straightness and concentricity over such a length while operating in a highly reactive chemical mixture at elevated temperatures (180°C).

Solution: We utilized 316L Stainless Steel for its chemical resistance and designed the Spindle with strategically placed stiffening elements. Our precision grinding capabilities achieved a total indicated runout (TIR) of less than 0.015mm over the entire length. A specialized PTFE coating was applied to the immersed section to prevent material buildup and enhance chemical resistance.

Outcome: The customized Spindle successfully integrated into the new reactor, enabling consistent mixing without excessive vibration or material contamination. The client praised the exceptional dimensional accuracy and the robust performance, leading to a follow-up order for additional reactor units.

Frequently Asked Questions (FAQ)

Q: What specific data is required to quote a custom Spindle?

A: To provide an accurate quote for a custom Spindle, we typically require detailed engineering drawings (CAD files preferred), material specifications, operational environment details (temperature, media, pressure), critical tolerances, surface finish requirements, quantity, and any applicable industry standards. Our engineering team can assist in defining these parameters if needed.

Q: How do you ensure the quality and reliability of your Spindles?

A: Quality assurance is integral to our process. We adhere to ISO 9001 standards and conduct multi-stage inspections, including raw material verification, in-process dimensional checks, non-destructive testing (ultrasonic, magnetic particle), hardness testing, surface roughness measurement, and dynamic balancing. Full material traceability and comprehensive test reports are provided with each order.

Q: What is the typical lead time for a custom Spindle?

A: Lead times for custom Spindle orders vary depending on complexity, material availability, and production queue. Generally, it ranges from 4 to 8 weeks after final design approval. We strive for efficient scheduling and clear communication throughout the manufacturing process to meet client timelines. Expedited options may be available for urgent requirements.

Q: What is your warranty policy for Spindle products?

A: We stand by the quality of our products. All our Spindles come with a comprehensive warranty against manufacturing defects. The specific warranty period typically ranges from 2 to 5 years, depending on the product type and application, and is detailed in our sales contract. Our customer support team is available to address any warranty claims promptly.

Logistics, Warranty, and Customer Support

Lead Time and Fulfillment

Our robust supply chain management and efficient production planning ensure timely delivery of your Spindle orders. For standard products, lead times are typically 2-4 weeks. Custom-engineered solutions usually require 4-8 weeks, depending on design complexity and material procurement. We provide transparent communication on production progress and logistics, offering global shipping solutions tailored to your project schedule and geographical location.

Warranty Commitments

Hebei Metals is committed to delivering products of the highest quality. Our Spindles are backed by a comprehensive warranty, typically ranging from 2 to 5 years from the date of shipment, against defects in material and workmanship. This commitment reflects our confidence in our manufacturing processes and the durability of our products. Specific warranty terms will be clearly outlined in your proposal and order confirmation.

Dedicated Customer Support

Our relationship with clients extends beyond product delivery. We offer dedicated technical support from experienced engineers to assist with installation guidance, operational troubleshooting, and maintenance best practices. Our global network ensures that expert assistance is available whenever and wherever you need it, minimizing downtime and maximizing the performance of your industrial assets. For inquiries, technical assistance, or support, please contact us via our official website or direct communication channels.

Authoritative References

- ASTM International. (n.d.). _ASTM Standards for Metals_. Retrieved from www.astm.org

- International Organization for Standardization. (n.d.). _ISO 9001:2015 Quality Management Systems - Requirements_. Retrieved from www.iso.org

- API - American Petroleum Institute. (n.d.). _API 610: Centrifugal Pumps for Petroleum, Petrochemical and Natural Gas Industries_. Retrieved from www.api.org

- Machining & Surface Finish Handbooks, various editions.

Copyright © 2025 Hebei Minmetals Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy