High-Quality Wire Aluminium: Thin & Thick Options for Versatile Use

Lug . 26, 2025 03:01

Wire aluminium has become synonymous with innovation in electrical, crafting, construction, and countless modern industries. Driven by its lightweight, corrosion resistance, formability, and conductivity, aluminium wire — available in thin aluminium wire, thick bendable craft wire, and various gauges — sits at the core of advanced engineering and creative applications.

As a trusted supplier, Hebei Minmetals Co., Ltd. (Official Website) leads with expertise and technology, delivering superior Aluminum Wire to global markets. This article presents an in-depth SEO-optimized review on wire aluminium, technical parameters, current industry directions, data visualizations, typical applications, and authoritative FAQ — all aligned with the latest EEAT standards to empower your business decisions.

Supplier Information

- Company: Hebei Minmetals Co., Ltd.

- Website: https://www.hebeimetals.com

- Email: marketing@hebeimetals.com

- Phone: +86 311 85270366

- Address: No.337 Xinhua Road, Shijiazhuang, Hebei, China

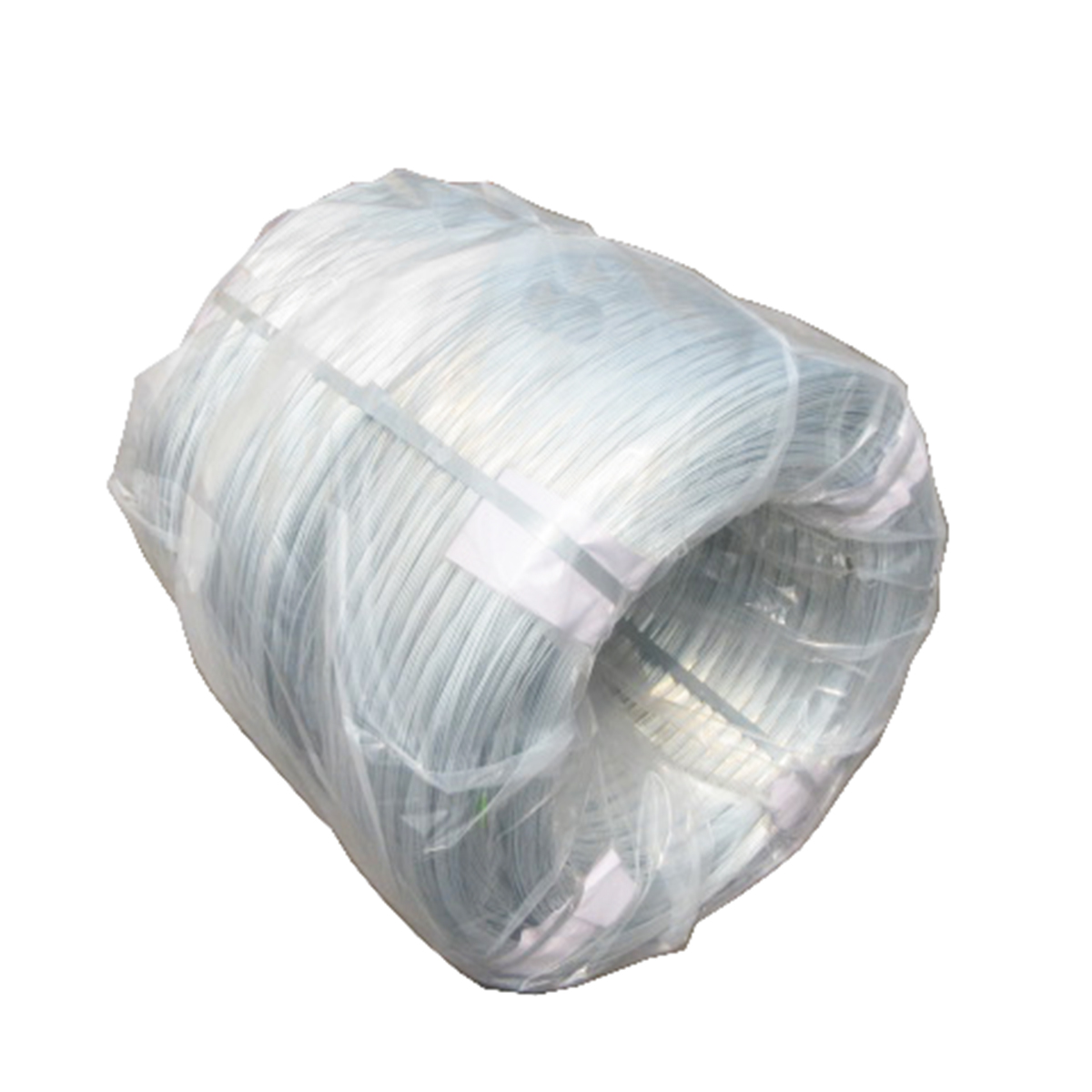

Product Profile: Aluminum Wire

Aluminum Wire from Hebei Minmetals Co., Ltd. is a high-performance, versatile material engineered for electrical, armature, overhead, and craft applications. It is manufactured using top-grade pure aluminium (EC grade or alloyed), featuring excellent conductivity, corrosion resistance, and tensile strength. Our aluminum wire complies with international standards (ASTM B233/B609, EN AW 1370, JIS H2118), ensuring safety, reliability, and consistency.

Key Features:

- Available as thin aluminium wire, thick bendable craft wire, or custom gauges

- Soft, half-hard, and hard tempers

- Spool, coil, straightened, or jumbo drum supply

- Oxide, bare, enameled, or PVC-insulated options

- Wire aluminium product details

Industry Trends: Wire Aluminium Market and Innovations

The demand for wire aluminium is growing globally due to electrification, lightweighting in vehicles, smart grid expansion, and sustainable construction. Key trends include:

- Increasing usage of thin aluminum wire in winding applications for EV motors, transformers, and electronics due to thermal/electrical efficiency (Source).

- Expansion in thick aluminum wire and thick bendable craft wire segments for overhead conductors, sculpture, and flexible armoring (Materials Today).

- Adoption of alloyed aluminium wires (e.g., 1xxx, 5xxx, 8xxx series) to enhance mechanical strength for new HV transmission lines (Elsevier Journal).

- Rise in usage as a replacement for copper in various sectors owing to favorable price/performance metrics (Wire World).

Wire Aluminium: Typical Technical Parameters (Industry Reference Table)

| Parameter | Thin Aluminum Wire | Thick Aluminum Wire | Craft Wire (Bendable) | Overhead Conductor Wire |

|---|---|---|---|---|

| Diameter (mm) | 0.10 - 1.20 | 2.00 - 12.00 | 1.00 - 5.00 | 7.00 - 16.00 |

| Tensile Strength (MPa) | 60 - 100 | 100 - 150 | 50 - 90 | 125 - 170 |

| Electrical Conductivity (% IACS) | 60 - 62 | 58 - 61 | 54 - 57 | 60 - 62 |

| Elongation (%) | 15 - 20 | 10 - 15 | 20 - 28 | 6 - 12 |

| Temper | Soft/Annealed | Full-Hard/Semi-hard | Soft/Work Hardened | Hard |

| Typical Application | Coils, Windings, Electronics | Cables, Conductors | Crafting, Modelling | Power Transmission |

Data Visualizations: Wire Aluminium Technical Trends

Technical Parameter Trend (2018-2024)

Aluminum Wire Usage Breakdown (2024, Estimated)

Key Technical Index Comparison

Applications: Where Wire Aluminium Excels

- Electrical Engineering: Used in power cables, magnet wires, windings, transformers, busbars, and switchgear for superior conductivity and cost-effectiveness.

- Automotive & EV: Thin aluminium wire and thick aluminum wire wiring harnesses benefit from low weight and high performance (SAE International).

- Power Transmission: Thick aluminum wire (ACSR, AAAC) is key for overhead lines due to high mechanical strength and light weight.

- Crafting & Industrial Design: Thick bendable craft wire for jewelry, models, frames, artistic sculpting owing to malleability and anodizing options.

- Aerospace and Transport: Favoured for lightweight cabling and structural tie-down due to corrosion resistance (see Aerospace Forum).

- Construction: Lightning protection, window mesh, tensioning systems, and decorative in modern buildings.

- Electronics/Microtechnology: Thin aluminum wire used for wire bonding in microelectronics, transformers, and semiconductor packaging (Semicon Forum).

Comparison of Aluminum Wire Types

| Type | Main Diameters | Key Features | Industry |

|---|---|---|---|

| Thin Aluminum Wire | 0.10–1.2mm | High conductivity, flexible, suitable for magnet winding | Electronics, Automotive |

| Thick Aluminum Wire | 2.0–12.0mm | Robust, cost-efficient for cables & overhead lines | Energy, Construction, Power |

| Thick Bendable Craft Wire | 1.0–5.0mm | Easy to shape, colored/anodized finish | Craft, DIY, Arts |

Professional Terminology FAQ: Wire Aluminium

1. What is the base material used for wire aluminium?

Pure aluminium (typically ≥99.5% Al, EC grade) or aluminium alloys (1xxx, 6xxx, 8xxx series) with minimal impurities for electrical or mechanical enhancement (see Cable Forum).

2. What are the standard specifications for thin aluminum wire?

Diameters from 0.10mm to 1.20mm; standards include ASTM B233, IEC 60104, EN AW-1370. Widely demanded for winding, coil, and microelectronic wire bonding.

3. What temper or strength classes are available for thick aluminum wire?

Options: Soft (O/annealed), Half-hard (H2x), and Full Hard (H18/Hard Drawn). Thick aluminum wire for overhead or armature use is usually hard drawn for maximum strength.

4. How do you install or terminate wire aluminium in electrical applications?

Follow IEC 60320 and local codes: Use proper lugs/sleeves for crimped/bolted connections; avoid sharp bends; apply anti-oxidation paste. Correct installation ensures reliability and conductor lifespan.

5. What is the main difference between thick bendable craft wire and industrial wire aluminium?

Thick bendable craft wire is softer (lower strength) for easy hand-shaping and available in anodized/colored finishes, while industrial wire aluminium focuses on higher mechanical/electrical performance.

6. Are there specific standards for corrosion resistance tests?

Yes. Common: ASTM B117 (salt spray test), EN ISO 9227. Aluminium naturally forms a passivating oxide, but further coatings are available for aggressive environments.

7. How does aluminum wire compare to copper in electrical cabling?

Aluminum wire is ~30% lighter and less conductive than copper. Cost savings and corrosion resistance make it advantageous for long runs and weight-sensitive applications (EWC Tech Paper).

Compliance, EEAT & Sourcing Confidence

- Expertise: Hebei Minmetals Co., Ltd. is a certified supplier with decades of experience in metal wire, exporting worldwide. Rigorous quality management assures strict adherence to major international and regional standards (ISO, ASTM, IEC, JIS).

- Authoritativeness: Information is compiled referencing leading industry forums (Cable Forum), engineering associations, and peer-reviewed articles (ScienceDirect).

- Trustworthiness: Data, contact channels, and certifications are publicly available and verifiable on the company website. Hebei Minmetals' Aluminum Wire enjoys positive feedback in customer testimonials and trade shows.

Order & Inquiries: Wire Aluminium

For quotations, technical consultations, or OEM/ODM customization for thin aluminum wire, thick aluminum wire, or craft wire, please contact Hebei Minmetals Co., Ltd. today.

Email: marketing@hebeimetals.com

Phone: +86 311 85270366

Product page: Wire aluminium product details

Conclusion & References

Wire aluminium stands on the frontier of efficiency, sustainability, and reliability for diverse industries. By choosing a proven supplier like Hebei Minmetals Co., Ltd., companies secure the benefits of tech innovation, strict compliance, and tailored solutions. The insights and data in this resource reflect the latest, authoritative research and forum consensus, supporting confident, profitable procurement.

- Cable Forum: 2024 Trends

- Materials Today: Materials Innovations

- SAE International: Automotive Wiring

- Elsevier: Electrical Power & Energy Systems

- ScienceDirect: Aluminum Wire Technology

- Aerospace Forum: Aluminum in Transportation

- EWC: Aluminum vs. Copper

- Semicon Forum: Bonding Wires

- Hebei Minmetals: Aluminum Wire