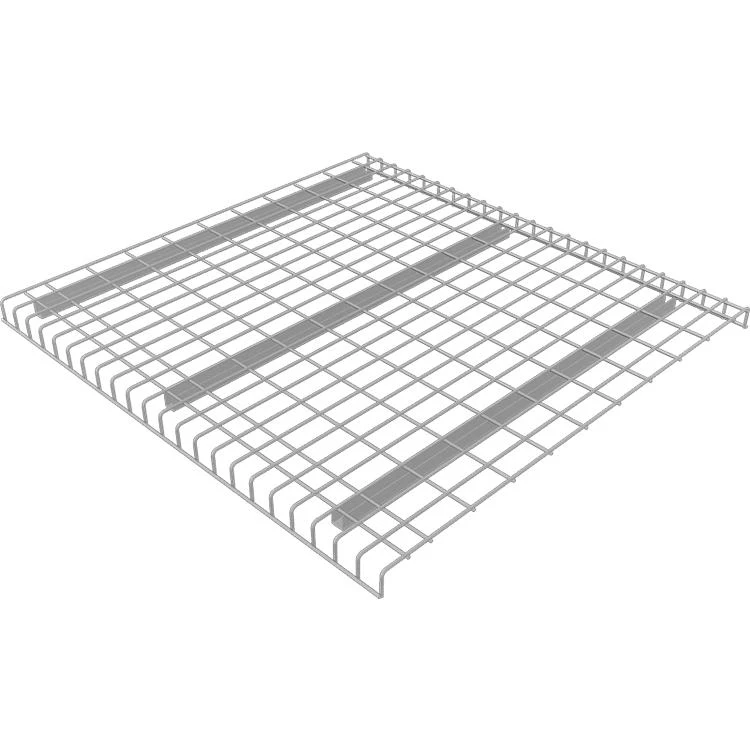

welded wire mesh

Nov . 02, 2024 05:18

Understanding Welded Wire Mesh Applications and Benefits

Welded wire mesh, a versatile construction material, has gained popularity across various industries due to its strength, durability, and adaptability. Comprising a grid of wires that are welded together at their intersections, this product is designed to provide structural integrity while allowing for various applications.

Composition and Manufacturing

Welded wire mesh is typically produced from high-quality carbon steel or stainless steel, which ensures that it can withstand various stresses and environmental conditions. The manufacturing process involves crossing wires at predetermined intervals and using an electric resistance welding technique to fuse them at the joints. This method creates a strong, uniform mesh that can be produced in different gauge sizes and configurations, catering to specific needs.

Applications in Construction

One of the primary uses of welded wire mesh is in the construction industry. It serves as a reinforcing element for concrete slabs, beams, and walls, enhancing the tensile strength and load-bearing capacity of structures. Additionally, welded wire mesh is often employed in road construction, where it supports the pavement and prevents cracking. Its ability to distribute loads evenly makes it ideal for various applications, from residential buildings to large-scale infrastructures such as bridges and tunnels.

Agricultural Uses

welded wire mesh

In agriculture, welded wire mesh is employed for fencing purposes and animal containment. It provides a secure barrier against predators while ensuring that livestock cannot escape. Additionally, it is used in greenhouse structures to support climbing plants or enclose growing areas, facilitating optimal growth conditions while keeping pests at bay. The adaptability of welded wire mesh in agricultural settings highlights its multifunctional nature.

Industrial Applications

In industrial environments, welded wire mesh plays a crucial role in storage and security. It is often used for creating shelves, cages, and enclosures, ensuring the safety of both personnel and equipment. The mesh allows for visibility and airflow while providing a sturdy barrier. Moreover, in manufacturing facilities, it is commonly used as safety guards and barriers to protect workers from machinery and hazardous areas, further underscoring its importance in ensuring a safe working environment.

Environmental Considerations

An additional benefit of welded wire mesh is its recyclability. Made from steel, it can be reprocessed and reused, contributing to sustainable building practices. Using recycled materials in construction is becoming increasingly important as industries strive to reduce their carbon footprint. Welded wire mesh, therefore, not only improves construction efficiency but also promotes environmental responsibility.

Conclusion

In summary, welded wire mesh is an invaluable material that spans various industries, from construction to agriculture and manufacturing. Its strength, versatility, and sustainability make it a preferred choice for many applications. As industries continue to evolve and prioritize safety and environmental responsibility, the demand for welded wire mesh is likely to grow, solidifying its place as a cornerstone in modern construction and industrial practices. Whether for structural reinforcement or safety barriers, welded wire mesh proves to be a reliable solution that meets the diverse needs of today’s market.

Unity

Unity Creation

Creation Challenge

Challenge Contribution

Contribution