-

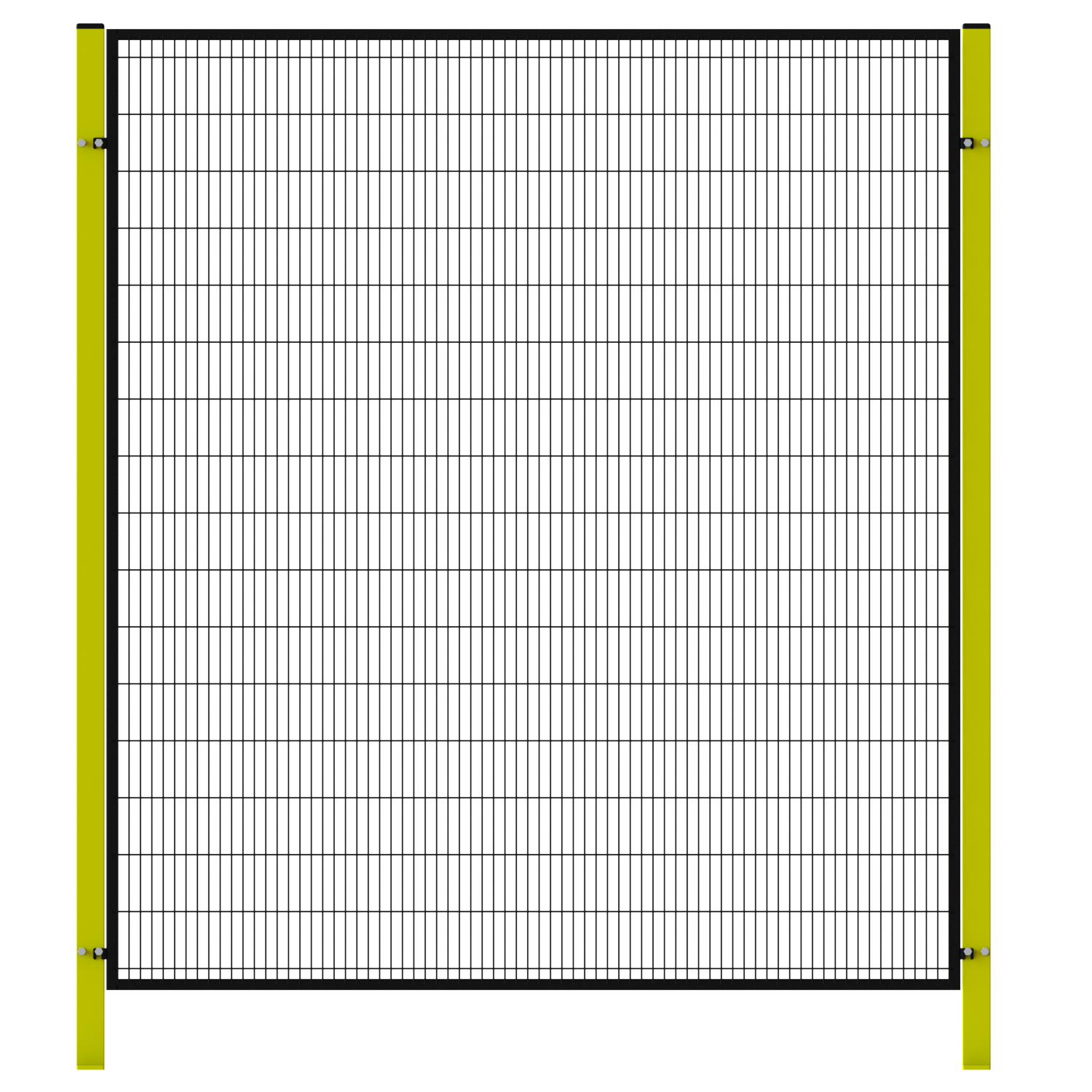

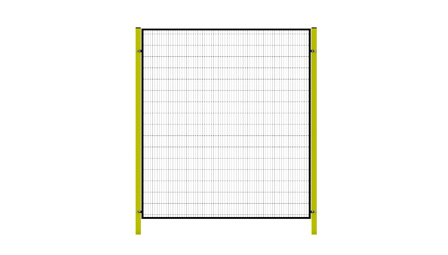

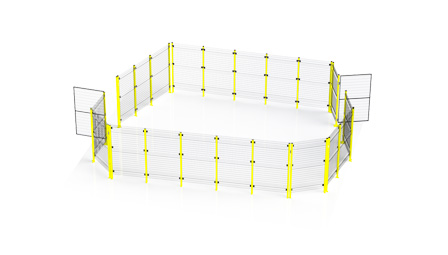

Con una gamma completa di componenti e accessori standard, il sistema MetalTec-Fence può aiutare a risolvere la maggior parte dei problemi di salute e sicurezza sul posto di lavoro.

-

Questa gamma completa di prodotti è sicura, semplice ed economica.

-

La natura modulare della protezione dei macchinari MetalTec-Fence consente infinite configurazioni ed è adatta a molte applicazioni.

-

Si tratta di un sistema di recinzione di sicurezza facile da montare che fornisce una chiara separazione tra lavoratori, macchinari e veicoli, proteggendo sia gli operatori che le attrezzature da lesioni o danni.

Descrizione

-

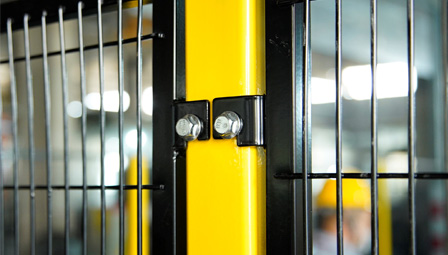

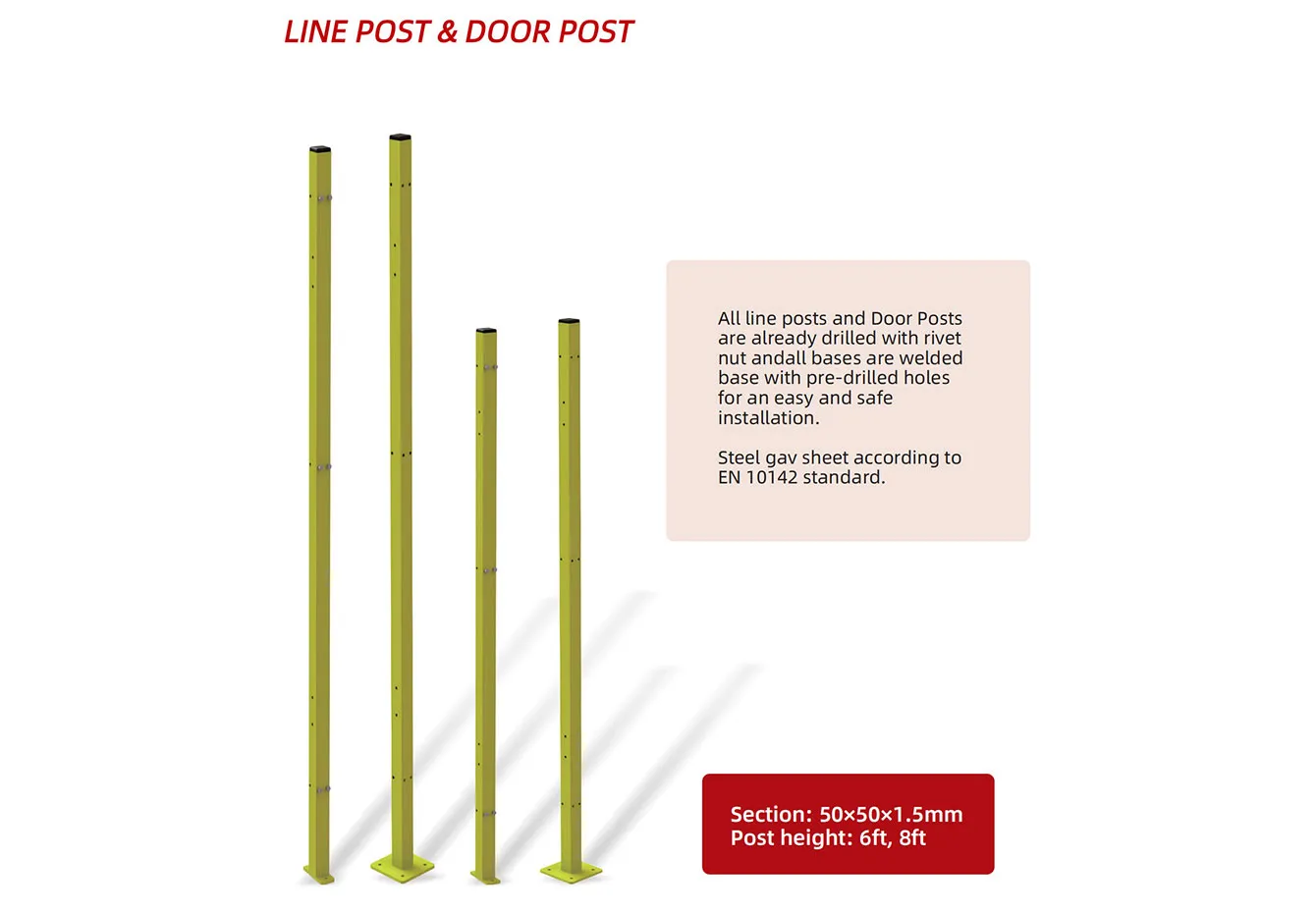

All line posts and door posts are already drilled with rivet nuts and all bases are welded bases with pre-drilled holes for an easy and safe installation.

-

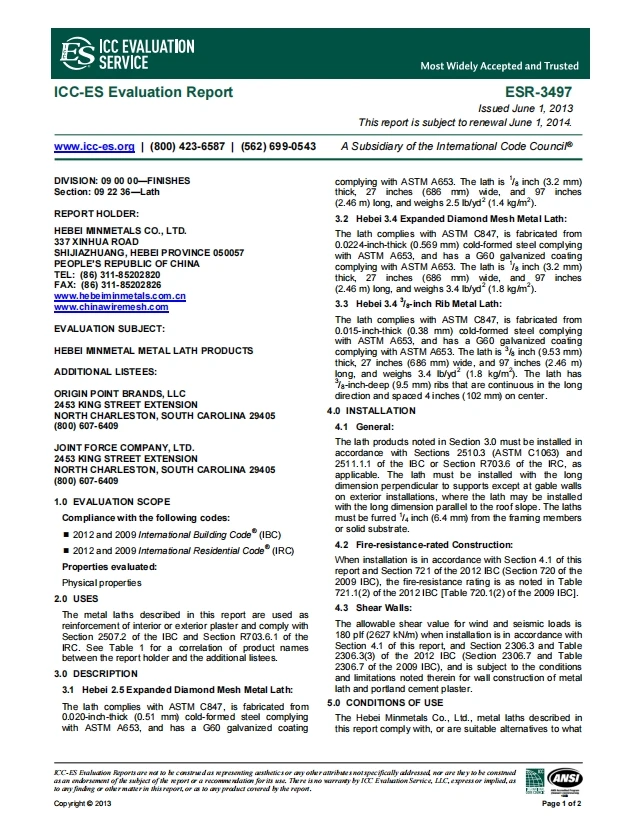

Steel GAV sheet according to EN 10142 standard.

-

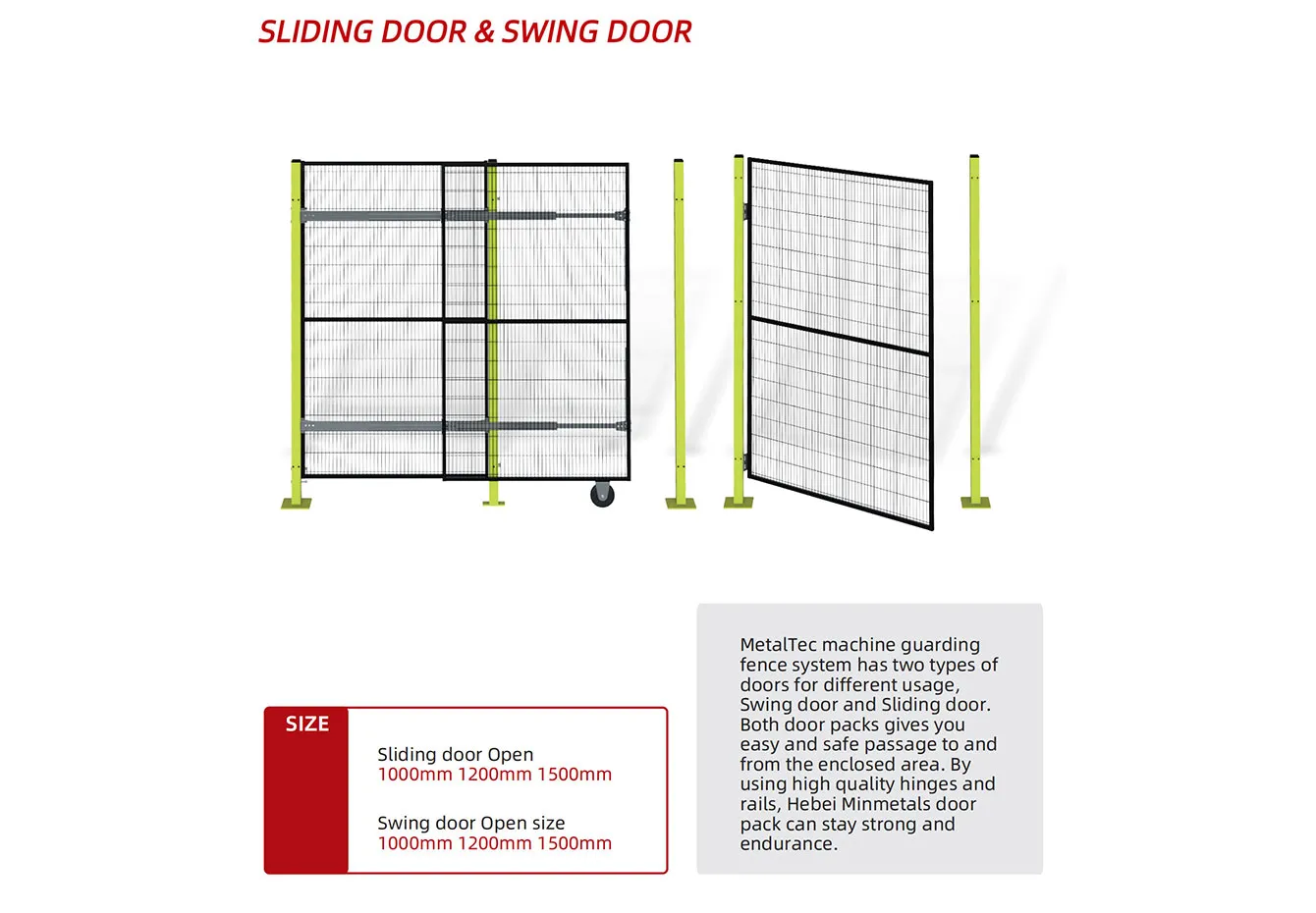

Metaltec machine guarding fence system has two types of doors for different usage, a swing door and a sliding door.

-

Both door packs give you easy and safe passage to and from the enclosed area.

-

By using high-quality hinges and rails, HEBEI MINMETALS door pack can stay strong and endure.

-

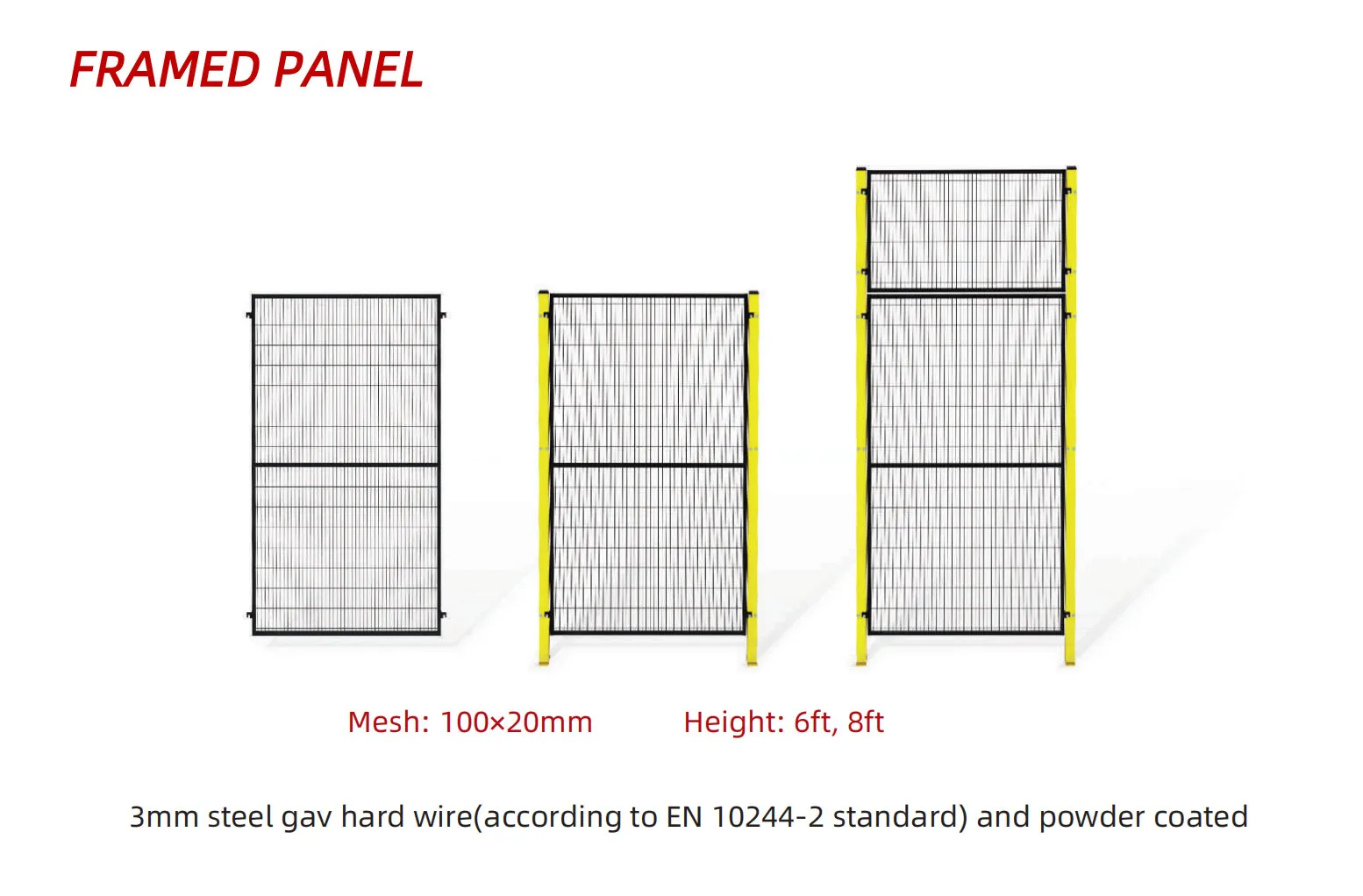

The framed panels and posts have been tested according to the recommendations on the impact tests described in ISO 14120:2015 annex C with the impact energies 1600J.

Vantaggio

Easy&Quick—Assembly

-

Con una gamma completa di componenti standard e base post-saldata con fori preforati, il nostro MetalTec può essere assemblato facilmente e rapidamente.

Anti-arrampicata

- I fili verticali esterni limitano gli appigli e scoraggiano efficacemente l'arrampicata.

Visibilità

-

Le feritoie verticali e la finitura verniciata nera garantiscono un'ottima visibilità del macchinario attraverso i pannelli in rete metallica.

Tagliare arbitrariamente

- Se necessario, i pannelli possono anche essere tagliati a misura o in altezza in cantiere e rifiniti con il kit di taglio.

| DESCRIZIONE | PARTE # |

| PANNELLO CON CORNICE 200 X 600 VERNICIATO NERO RAL9OO5 | FP200X600 |

| PANNELLO CON CORNICE 300X600 VERNICIATO NERO RAL9O05 | FP300X600 |

| PANNELLO CON CORNICE 700 X600,VERNICIATO NERO RAL9OO5 | FP700X600 |

| PANNELLO CON CORNICE 800 X 600 VERNICIATO NERO RAL9OO5 | FP800X600 |

| PANNELLO CON CORNICE,1000 X600,VERNICIATO RAL9005 NERO | FP1000X600 |

| PANNELLO CON CORNICE 1200 X600 VERNICIATO NERO RAL90O5 | FP1200X600 |

| PANNELLO CON CORNICE 1500X 600 VERNICIATO NERO RAL9OO5 | FP1500X600 |

| PANNELLO CON CORNICE 200 X1688 VERNICIATO NERO RAL9005 | FP200X1688 |

| PANNELLO CON CORNICE.300X1688,VERNICIATO NERO RAL90O5 | FP300X1688 |

| PANNELLO CON CORNICE,700 X1688,VERNICIATO NERO RAL9OO5 | FP700X1688 |

| PANNELLO CON CORNICE,8O0X1688,VERNICIATO NERO RAL9O05 | FP800X1688 |

| PANNELLO CON CORNICE,1000X1688,VERNICIATO RAL9005 BIANCO | FP1000X1688 |

| PANNELLO CON CORNICE,1200X1688,VERNICIATO NERO RAL90O5 | FP1200X1688 |

| PANNELLO CON CORNICE 1500X1688 VERNICIATO NERO RAL9OO5 |

FP1500X1688 |

| DESCRIZIONE | PARTE # |

| PANNELLO SENZA CORNICE 300 X 600, VERNICIATO NERO RAL9OO5 | UP300X600 |

| PANNELLO SENZA CORNICE 500X600 VERNICIATO NERO RAL9O05 | UP500X600 |

| PANNELLO SENZA CORNICE 800 X600 VERNICIATO NERO RAL9OO5 | UP800X600 |

| PANNELLO 1000X600 NON ACCIAIO VERNICIATO NERO RAL9005 | UP1000X600 |

| PANNELLO 1200 X600 NON ERAMMATO,VERNICIATO NERO RAL9005 | UP1200X600 |

| PANNELLO SENZA CORNICE 1500 X 600 VERNICIATO NERO RAL9OO5 | UP1500X600 |

| PANNELLO SENZA CORNICE 1800 X 600 VERNICIATO NERO RAL9OO5 | UP1800X600 |

| PANNELLO SENZA CORNICE 2400 X600 VERNICIATO NERO RAL9OO5 | UP2400X600 |

| PANNELLO SENZA CORNICE 300X1688 VERNICIATO NERO RAL9OO5 | UP300X1688 |

| PANNELLO SENZA CORNICE 500 X1688 VERNICIATO NERO RAL9OO5 | UP500X1688 |

| PANNELLO SENZA CORNICE 800X1688 VERNICIATO NERO RAL9OOS | UP800X1688 |

| PANNELLO SENZA CORNICE,1000 X1688,VERNICIATO NERO RAL9O05 | UP1000X1688 |

| PANNELLO SENZA CORNICE,1200X1688,VERNICIATO NERO RAL90O5 | UP1200X1688 |

| PANNELLO SENZA ACCIAIO,1500X1688,VERNICIATO NERO RAL9005 | UP1500X1688 |

| PANNELLO SENZA CORNICE 1800 X 1688, VERNICIATO NERO RAL9OO5 | UP1800X1688 |

| PANNELLO SENZA CORNICE 2400 X1688 VERNICIATO NERO RAL9O05 | UP2400X1688 |

Customizable Framed Machine Guard Panel Systems for Maximum Industrial Safety

Why Choose Framed Machine Guard Panels?

Engineered for versatility, our systems allow seamless customization to fit CNC machines, robotic arms, conveyor belts, and other industrial equipment. Unlike fixed barriers, framed panels offer easy reconfiguration as your layout evolves, minimizing downtime. Choose between heavy-duty steel for high-impact zones or lightweight polycarbonate for visibility and corrosion resistance—all while maintaining optimal airflow and accessibility for maintenance.

Key Benefits:

Enhanced Safety: Reduce workplace injuries with panels that eliminate exposure to moving parts, sparks, and debris.

Cost Efficiency: Modular designs cut long-term costs by adapting to changes without full replacements.

Compliance Assurance: Pre-installed mounting points and tamper-proof latches simplify adherence to regulatory audits.

Industries We Serve:

From automotive manufacturing to food processing, our machine guard panels are trusted in sectors demanding precision and reliability. Pair them with IoT-enabled sensors (optional) for real-time monitoring, creating a smart safety ecosystem aligned with Industry 4.0 trends.

Expert Support:

Our team guides you from design to installation, ensuring panels meet your facility’s exact specifications. Schedule a consultation today.

Versatile Framed Machine Guard Panels for Every Industrial Setting

The framed machine guard panel is a smart and reliable solution for safeguarding both workers and machinery in a wide variety of industrial environments. Whether you operate in manufacturing, automation, logistics, or assembly lines, Hebei Minmetals’s machine guard panels offer modular protection that meets rigorous safety standards. Each panel is made of high-strength steel and powder-coated in RAL9005 black, delivering excellent corrosion resistance and visibility. The pre-drilled posts and welded bases simplify installation, while the system's modular design allows for seamless customization to fit unique floor plans and operational needs.

What sets these framed machine guard panels apart is their tested impact resistance up to 1600J, in compliance with ISO 14120:2015, ensuring maximum durability in high-risk areas. With optional swing or sliding doors, operators can access enclosed zones quickly and safely. The vertical wire design discourages climbing and allows clear views of machinery operation, helping improve workplace awareness and efficiency. If needed, the panels can also be cut on-site and finished with cut kits, providing unmatched flexibility during setup.

From compact workshops to large-scale automated facilities, Hebei Minmetals’ machine guard panels create strong physical barriers that are easy to install, configure, and maintain. Ensure regulatory compliance, protect your personnel, and streamline your safety procedures with our dependable guarding solutions.

Cost-Effective Machine Guarding: Framed Panels vs. Framedless Panel

Choosing the right machine guarding solution impacts both safety and your bottom line. When comparing framed machine guard panels and frameless panels, understanding their cost-effectiveness, durability, and suitability for your facility is critical. Here’s a breakdown to help you decide:

Framed Machine Guard Panels: Strength Meets Flexibility

Durability: Steel or aluminum frames provide structural rigidity, ideal for high-impact environments (e.g., automotive, heavy machinery).

Modularity: Pre-drilled posts and standardized components allow quick assembly, reconfiguration, and scalability as needs evolve.

Compliance: Tested to ISO 14120:2015 standards (e.g., 1600J impact resistance), ensuring adherence to OSHA and ANSI regulations.

Long-Term Value: Reduced maintenance costs and extended lifespan due to robust construction.

Frameless Machine Guard Panels: Lightweight & Budget-Friendly

Lower Upfront Cost: Simplified designs and fewer materials make frameless panels ideal for tight budgets.

Lightweight: Easier to install and reposition, perfect for dynamic or temporary setups.

Custom Sizing: Panels can be trimmed on-site for irregular machinery or space constraints.